FW

The Philippines cotton industry is facing huge competition on home turf as the United States cotton sector officials were scouting the country for local manufacturers to carry their products. As Cotton Council International ASEAN representative, Kraipob Pangsapa points out, demand for cotton grew in the Philippines, but the use of US cotton had shrunk. Pangsapa says they have to increase sales by five per cent this year and growth will fast forward if more deals are sealed with Phinilippine manufacturers.

According to the Cotton Council International, of the average 40,000 metric tons of lint consumed by the country per year, valued at $66.57 million, at least 97 per cent of cotton is being imported, mainly from the US. The local industry, inspite of favourable soil and climate, is facing a major setback due to numerous socio-economic and technical factors, such as the cotton bollworm issue.

Pangsapa says to address and aid rising demand of cotton in the country, Cotton US plans to partner with two big local brands to introduce their products to buyers. The Cotton Council International has 19 licensees divided into six categories: women’s wear, men’s wear, men’s innerwear, children’s wear, home textiles, and personal care.

Cotton USA brand was introduced to garment manufacturers and consumers in 1994 and on June 26, the CCI’s, marketing and promotions arm of the United States cotton industry, formally re-launched its 26-year-old flagship brand Cotton USA in the Philippines. And as Cotton Council International President Dahlen Hancock says their brand has been highly successful. The new generation of consumers needs to hear why cotton is such a wonderful product and why U.S. cotton is the premier cotton for textile and garment manufacturers and consumers. Usage of raw US cotton has reduced in Philippines but in the consumer and retail side, Philippines is stronger than Thailand.

South Africa faces factory closures resulting in thousands jobs losses. According to Etinne Vlok, the director of South African Clothing and Textile Workers Union’s South African Labour Research Institute (Salri), the South African clothing industry’s tough times are due to the lack of support from the local clothing retailers. This has also resulted in factory closures and thousands losing their jobs.

The latest employment statistics from Stats SA reveals there have been job loses in due to closer of factories. The data, based on Quarterly Employment Survey (QES) for the March 2015 quarter showed that there was a year-to-year rise of 1.5 per cent in the number of people employed across the CTFL industry from March 2014 to March 2015. Besides, there was a 1.5 per cent rise in number of employees from December 2014 to March 2015. The sector saw a rise in total number of employees, from 87,386 to 88,657 year-to-year and from 87,319 to 88,657 quarter-to-quarter.

However, the clothing sector’s overall national numbers dropped from 210,000 to around 100,000 between the years 2002 and 2010, mentioned Vlok. Vlok added, as Stats SA only records national figures and not provincial ones, he estimated the numbers in this sector of the Western Cape dropped by a similar total over the same period—from about 80,000 to about 30,000 currently. It was caused by a flood of cheap imports, both legal and illegal, mainly from China.

This means products manufactured locally are able to compete better with imported ones. In 2000, the situation was the reverse, it was cheaper to import, which contributed to the jobs bloodbath in clothing sector. It is against this backdrop that one looked at the numbers from the Stats SA survey, which showed a small increase. Vlok further said the industry was stabilising and numbers in the survey too further confirm this.

Indorama Synthetic's first quarter revenues fell 5.41 per cent compared to the same period last year. But for the second half of the year, revenue will be driven by additional production capacity of mill spun yarn. The budgeted capital expenditure this year will be used to increase production capacity at the mill spun yarn capacities in Indonesia and Uzbekistan. Meanwhile, total production has reached 60 million meters a year, and polyester production capacity is 277 thousand tons a year.

The company exports to 80 countries around the world such as North America, South America, and Europe. In 2014 exports were equivalent to 67 per cent of total revenue. In the first quarter of this year, exports reached 67.89 per cent of total revenue. Indorama has three factories. For now, the focus is on spun yarn. Increased production capacity is expected. The company is looking to increase revenues in 2015, amounting to $850 million, up from last year’s $726.02 million.

The company was incorporated in 1986. Indorama Synthetics is one of Indonesia’s largest exporters. A continuous process of reinvestment and productivity enhancement programs has made Indorama Synthetics one of the most competitive producers of polyester worldwide.

The spun yarn division accounts for over 20 per cent of the company’s revenue. With a capacity of over 2,50,000 spindles and over 50 per cent of its output being exported, the company is one of the largest exporters of spun yarn in Indonesia.

www.indoramaindia.com/

Designers Teatum Jones (Catherine Teatum and Rob Jones) and Agi and Sam (Agape Mdumulla and Sam Cotton) are the winners of international Woolmark prize for British Isles in women’s and men’s wear categories respectively. Teatum Jones are known for their use and development of merino wool, from concept to the final garment. The pair were chosen from eight shortlisted talents.

The Woolmark prize is a global search for the world’s best emerging design talent. It has entered its fourth year. With a record 70 labels nominated across 23 countries, this year’s prize will propel a fresh crop of fashion stars into the spotlight, showcasing new and innovative ways to work with Australian merino wool.

Each regional finalist receives a cash sponsorship and the opportunity to compete in the final. The winning merino wool capsule collection of the overall winner will be stocked in a dozen of the world’s most prestigious fashion retailers.

Chosen by some of the globe’s most prestigious fashion bodies and set to be critiqued by a judging panel of industry heavyweights, these stand-out designers will each compete within their region for a chance to win the international Woolmark prize.

www.woolmarkprize.com/

Things are going from bad to worse at American Apparel. The Los Angeles-based US fashion retailer, is experiencing low sales as its debt mounts. It fears it might not be able to meet funding commitments for the next 12 months even if it increases revenue and cuts costs.

The brand is best known for its racy advertising and its practice of making its clothes in Los Angeles' garment district rather than in Asia. American Apparel has racked up about 340 million dollars in net losses in the last five years. It has more than 200 million dollars in debt and negative shareholders’ equity.

The company has been embroiled in boardroom turmoil, and last year ousted its controversial chief executive Dov Charney in a public clash. Earlier this year, it announced plans to raise as much as $10 million from share sales after it reported a jump in first quarter losses. American Apparel has announced $30 million cost cutting measures in a bid to stabilise business. This includes job cuts and store closures. The retailer operates 239 stores and employs 10,000 workers. It plans to close underperforming retail locations in unprofitable and over-saturated markets and looks to add new stores in profitable fast-growing territories.

store.americanapparel.net/

Chinese wool buyers and processors are well aware of the differences in wool types across the world. They understand fully that two of the critical factors in any buying and processing decision are the micron and color of the wool. These dictate use and yield. And the Welsh industry says its wool has been sampled to internationally recognised standards and tested using the same methods and quality controls as those used in other principal wool testing laboratories across the world.

The Chinese market is important for UK wool producers. It normally takes at least a month for wool shipments to reach China from Wales. Great care is taken at all levels of the British wool supply chain from farm onwards. A high level of skill is employed at every level of the wool supply chain in the UK. About 30 per cent of British wool now finds its way to China.

Wool has historically the most important and widespread of Wales’ industries. Traditionally, woven Welsh wool blankets and throws are popular not only in the UK but across the world. Wool is a 100 per cent natural fiber and has evolved to become one of the most effective natural forms of all-weather protection known to man.

Denim units in Bangladesh are in top gear. Hundreds of units are operating to deliver on huge orders for denim products ahead of Id. To cope with growing orders, workers have been working till midnight to meet demand of country's large local customer base. Targeting hot Id sales, some manufacturers have also raised their investment volume for further mounting their production capacity in a bid to book a good portion of the hefty trade during the largest festival for Muslims.

Keraniganj, located on the banks of river Buriganga, is home for more than 5,500 small and medium-sized factories, mostly denim, they make various types of clothing. The hub is a cluster of 200 units spread over two kilometers area. The apparel zone supplies around 80 per cent of Bangladesh’s total demand for denim.

Wholesalers and retailers from all over the country come to purchase good-quality wear from the cluster, which was known for supplying re-modified used clothes in the 80s. The whole chain of manufacturing includes sewing, dyeing and washing is on a desperate run to maintain smooth supply of quality fashion wear for both men and women.

Japan will support Pakistan in boosting the value added textile sector's exports and will provide assistance for product diversification, international marketing and enhancing capacity building of garment institutes. In the early 1990s, Japan provided similar assistance, which yielded a positive impact on the quality and productivity of the textile sector.

Japan and Pakistan have discussed parameters for the project of skill development and market diversification for the garment industry. Japan would facilitate Pakistan’s garment sector especially small and medium enterprises in the field of international marketing practices along with compliance requirement, marketing and product diversification.

Japan coordinated with Pakistan’s textile sector in 1993 and helped upgrade the National Textile University, Faisalabad. The new project will open a new era of cooperation between the two countries and will provide technical assistance in different fields of the textile sector. The project would facilitate in achieving goals and objectives set forth in the Textile Policy 2014-19. Japanese companies are already working in health, education and energy sectors of Pakistan.

But a high rate of import duty deters Japan from importing textiles from Pakistan. Japan is the world’s largest importer of textiles and prefers Sri Lanka and India with a relatively low ratio of taxes.

Sourcing at Magic will take place in the United States from August 16 to 19. It showcases the latest in apparel, footwear and accessories for men, women and children. This is a fashion trade show that happens twice a year and meant for large buyers as also small and medium businesses.

It’s North America's largest, most comprehensive sourcing event. Thousands of exhibitors showcase next season’s collections. The show expects more than 2,000 exhibitors from 24 countries. A variety of seminars hosted by top industry professionals will be open for attendees and exhibitors. Magic is unique because it shows and blends a variety of brands alongside a variety of factories from around the world. It covers advanced contemporary luxury brands to the latest trends in fast fashion.

A mobile app will help assist exhibitors as well as visitors. It is a searchable database. Within the app a search can be made by country of origin, name of factory, products and minimums. A digital matchmaking service will allow attendees to find the manufacturers that will best fit their production needs. Sourcing at Magic is focusing on wearable technology this August. There will be an interactive exhibit area.

www.magiconline.com/sourcing-at-magic

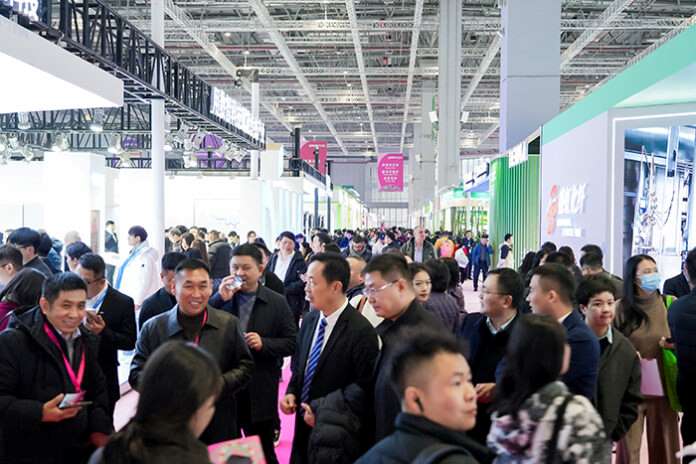

For 20 years, Hong Kong Fashion Week for Spring/Summer has enjoyed an international reputation for excellent sourcing in a highly professional environment. More than 1,200 exhibitors from 18 countries and regions are taking part in the 22nd HKTDC Hong Kong Fashion Week Spring/ Summer ’16 which runs from July 6 to 9 at the Hong Kong Convention & Exhibition Centre (HKCEC).

Eight groups pavilions, including the event’s largest from the Chinese Mainland, are representing a diverse range of markets, including Japan, Thailand, India and South Korea.

India in focus at HKFW

India has emerged as the second largest exporter of textiles after Mainland China. With a supply chain covering production of cotton fibres, fabrics and garments, India’s textile and garment manufacturers are highly competitive in the world market. To promote garment industry, the Apparel Export Promotion Council has organised the Indian Pavilion at Hong Kong Fashion Week for Spring/Summer for the 13th consecutive year.

“This year, we have come with 65 Indian companies to promote casual garments for men, women and kids; scarves; shawls; sweaters and T-shirts which are all made in India. Hong Kong Fashion Week is an international show that draws buyers from all over the world. A lot of customers from European and the US buying offices in Hong Kong visit this fair regularly to look for new vendors. That’s why Indian companies have maintained a strong presence in the fair,” said Pravin Agarwal, Executive Committee Member, Apparel Export Promotion Council.

Wide zones display the latest

Under the theme ‘Tribal Safari’, the fashion week features a wide array of product zones including; ‘International Fashion Designers’ showcase, ‘Emporium De Mode’, ‘Fashion Jewellery Feast’, salon of Scarves and Shawls, Denim Arcade and Bridal & Evening Wear.

Fashion Gallery is the largest zone, showcasing designer labels and top brands, while International Fashion Designers’ Showcase is an exciting space for trend-setters. Men in Style segment gives exhibitors of menswear prominence. Retailers are value-adding through accessories and exhibitors are catered for in a number of zones such as World of Fashion Accessories, Handbags Select, Salon of Scarves and Shawls and Fashion Jewellery Feast.