FW

Woolfest 2014 will be held at England Mitchell’s Lakeland Livestock Centre on June 28 and 29. This is an event that displays the best in wool crafts and offers a wealth of advice for any natural fiber enthusiast. Visitors have a chance to find out more about a new craft or learn a new skill in one of the many demonstrations taking place. This year they have the opportunity to discover more about wet felting, weaving and extreme textiles.

The event also offers visitors a chance to meet makers and designers as well as the opportunity to learn more about British wool. This year, the festival will celebrate the native Herdwick sheep. Readings, images and music will provide an informative yet entertaining take on the iconic breed. Wool fans can purchase a two-day ticket and take part in many of the creative projects that will be happening throughout the festival.

In 2013, the event had attracted more than 6,000 visitors and picked up a number of awards from industry publications including being voted as favorite event.

www.woolfest.co.uk/

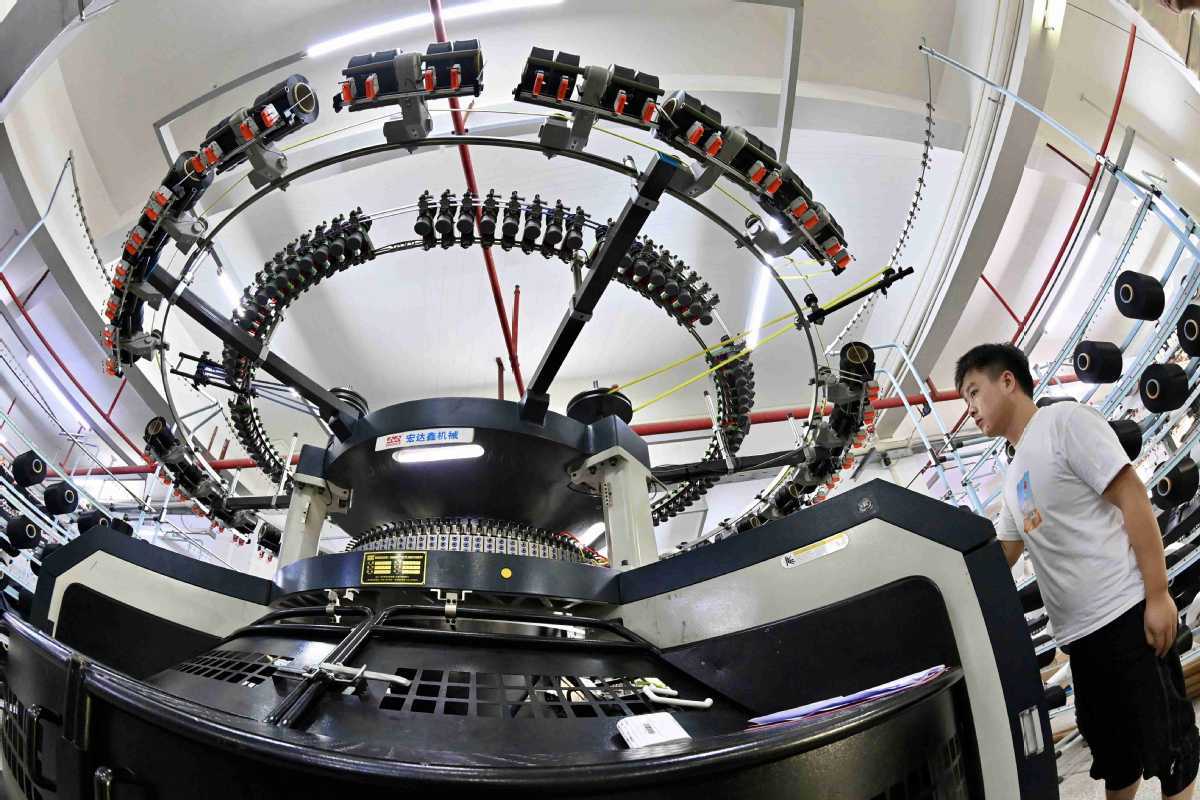

Mosi or fine ramie fabric is a traditional Korean fabric. Mosi cloth weaving starts with the ramie plant. It’s one of the oldest fibers cultivated for fabrics. The ramie is peeled off and then split to be made into threads. It takes great effort to make a fabric out of ramie plants, as there are many steps involved in it. To make a suit, the weaving process alone takes about 10 days.

The handmade ramie fabric is also called Jeomapo or Jeopo. Mosi is known for being light, breathable and holding its shape easily. For this reason, Mosi has long been regarded as the ideal fabric for summer attire. It is made by hand weaving strands of durable bast fiber from stems of the ramie plant, a member of the nettle family. Whenever a garment made of Mosi is washed, it becomes more lustrous and white, which gives it a fresh look and feel after each wash.

As weaving Mosi is an arduous task that calls for an experienced and dexterous hand, it was treasured as a precious fabric. This strong, yet airy natural fabric has inspired modern fashion designers like Seo Young-soo, who recently held a collection composed of pieces made of Mosi fabric.

SPINEXPO, the international exhibition for yarns, fibers and knitwear, will be held July 15 to 17 in New York. More than 80 exhibitors from 15 countries will display an array of tactile and colorful yarns from internationally acclaimed spinners and knitwear manufacturers, including fibers such as cashmere and mohair, merino wools, silk, viscose, metallic and synthetics.

The Cashmere Boutique is a special area that aims to create a pop-up boutique focused purely on a new generation of cashmere, highlighting a fiber which can be technical, light and fashionable even in spring/summer. Working with a bright palette, stylists, spinners and knitwear manufacturers have worked hand-in-hand to create mini capsule designer collections to show cashmere in a whole new light.

The general Trend Area shows a fusion of active wear and technological crafts. Active sportswear influences daily fashion and shows stretch, knit and fabrics that are technologically enhanced to offer more comfort and ease of wear.

Among the companies participating are Bros Holding and Yarns & Colors. Bros Holding specialises in top-dyed mélange yarn. Yarns & Colors offers eco-friendly products, ranging from natural fibers to high performance synthetic fibers, single materials to sophisticated blends, and all kinds of spun yarns to fancy twisted yarns.

www.spinexpo.com/

After European Union (EU) granted GSP Plus status to Pakistan, the country has been reaping benefits of duty-free access to European markets. It was evident as textile garment exports grew almost 31 per cent in the first two months after the trade preference scheme came into force, according to official statistics released by the Ministry of Commerce.

As per sector-wise analysis, exports of textile garments grew significantly by 30.68 per cent against last year’s shipments in January and February. Total sales of textile garments to the EU in the two months last year stood at $342 million, which grew to $446.91 million this year, recording an increase of $105 million or 30.7 per cent.

From January 2014, the EU granted duty-free access to Pakistan for a period of 10 years, but its continuation is subject to periodical reviews that will determine whether Pakistan is making progress on over two dozen conventions of the United Nations pertaining to human, labour and gender rights and freedom of expression.

Experts estimate that GSP Plus will result in almost 20 per cent of Pakistan’s exports entering the EU market at zero tariff and 70 per cent at preferential tariff rates. This status will enable exporters to boost overseas sales by more than one billion dollars. Only the textile industry would earn profits of more than Rs one trillion per year, according to the Ministry of Commerce.

The Ministry of Commerce said exports of home textiles to the EU in January-February 2013 amounted to $214.18 million, which rose to $274.47 million in the same period this year, showing an increase of 28.15 per cent. Leather and carpet manufacturers were also successful in making a strong mark as they enhanced their share in the European market after the grant of GSP Plus with shipments increasing 15.20 per cent and 12.79 per cent respectively during January and February 2014. The leather sector exported goods worth $25.46 million this year, up from $22.10 million in the corresponding period of previous year.

Commerce.gov.pk

The leaders of the apparel sector in Bangladesh have sought government action against rights groups who are engaged in tarnishing the image of the country’s garment industry abroad. These are labor rights groups that have lodged complaints to different international organisations bypassing the government and other local stakeholders.

Heads of the apparel sector say if there is any such incident of workers' oppression in garment factories, the complaint should be first lodged with the local authorities concerned instead of engaging in a conspiracy against the industry. Some labor leaders have alleged to have lodged complaints with a US authority that Bangladesh garment workers are oppressed.

Rights groups say the Bangladeshi government should stop garment factory owners from intimidating and threatening workers who organize trade unions. Some union organizers say they have been beaten up, and others say they have lost their jobs or been forced to resign. More than 50 factory-level unions have been established. But the law still requires union organizers to get the support of 30 per cent of factory’s workers before registering a union. Employer threats and intimidation make it a difficult task, especially in factories employing thousands of people.

The Sri Lanka Apparel Brands Association (SLABA) has been launched in Colombo. It was earlier called the Domestic Garment Manufacturers Association (DGMA). SLABA’s objectives are: to gain both local and international recognition as the hub of Sri Lanka’s apparel brands; operate as a facilitator to develop the branded apparel segment among newcomers in the industry; take Sri Lankan brands to the international arena and establish them globally.

It will provide a common forum for the diverse product portfolio of branded apparels representing casual wear, tailoring and formal wear, fashion wear, uniform and work wear, lingerie, and other products such as socks, head wear, bags etc. Sri Lankan brands account for 40 per cent of the country’s estimated $2 billion retail apparel market. The association wants to be seen as one which encourages branded quality products for the consumer. It plans to expand market opportunities through the introduction of international market places (as in Thailand, Indonesia and China) for tourists and business travelers with a variety catering to all segments. It will also shape the policies that impact the apparel industry in the domestic market through dynamic lobbying with both government and non-government organizations.

The competitiveness of the Chinese clothing industry is set to weaken over the next few years as costs rise. As a result, export growth could falter. Rising costs in China are already forcing many western apparel brands and retailers to cut back on their sourcing from China and have their apparel manufactured elsewhere. In response, the Chinese government is pursuing a policy of encouraging growth in the domestic clothing market in order to take up slack in its manufacturing sector caused by this apparent loss in competitiveness.

The rise in costs in China stems in part from significant increase in fuel costs and shipping costs. Also, wage rates have risen to the point where they are higher than in many other Asian countries. Early signs of a shift in apparel manufacturing have been seen in EU and US clothing import trends. In 2013, China’s share of EU clothing imports from all sources in value terms fell from 41.7 to 40 per cent. China’s share of US clothing imports from all sources fell from 37.8 to 37.3 per cent.

The strongest growth in EU clothing imports in 2013 was in imports from Bangladesh, Cambodia and Pakistan, while the strongest growth in the US clothing import market was in imports from Bangladesh, Sri Lanka and Vietnam.

From April 2013 to January 2014, India exported 1,082 million kg of cotton yarn. India's cotton yarn exports are meeting their targets barring the seasonal fluctuations generally witnessed every April in spite of high raw cotton prices. The high quality of Indian yarn is ensuring firm orders for Indian mills from international markets.

Exports of cotton yarn dropped during the last three years in the month of April and it happened in 2014, too. One of the reasons, in addition to the high year-end exports which cause a drop in April, is the temporary high cotton prices during this period.

There is an increasing anxiety in the industry due to China’s recent cotton policy. China is the major importer of cotton and cotton yarn from India. Presently, the price difference between Indian and Chinese cotton is quite high with Indian yarn selling at much lower rates. In fact, prices of Indian cotton yarns after payment of duty and taxes in China are still much lower than Chinese domestic yarn prices.

Given the better quality produced by Indian mills it’s expected there will always be good exports of Indian yarns, even if the difference between Chinese cotton prices and international cotton prices narrows down substantially.

The Kenyan government has taken up the task to revive its textile and leather sectors. It is working to lower the costs of locally produced goods that compete with imported goods. The aim is improve efficiency in manufacturing companies in order to boost trade in the country. Delays caused by congestion at ports and poor road conditions have been blamed for cancelled orders from apparel buyers. The government has decided to provide assistance to the textile industry by bringing down the cost of production, lowering the cost of power, improving the quality of roads to ensure market accessibility and improving value addition of raw products.

It would also work on issues like influx of cheap imports from Asia which pose unfair competition to local producers, imports of secondhand garments, delays in sourcing of raw material. Demand for leather in Kenya is a high 28 million units annually, but since production is heavily reliant on imported supplies, the current local supply is less than four million units annually.

Kenya has ideal production zones for quality leather. Since the global leather demand is now $60 billion, it can work towards grabbing a share of the cake.

China may cut down on cotton yarn purchases this fiscal, slowing the good run that Indian spinning mills had had last year. Recovering from a rough patch in the previous few years, spinning mills across India did good business last fiscal with a surge in demand in the Chinese market.

Idle mills sprang to life across the southern states, boosted by healthy cotton production and the government’s decision to make yarn export eligible for benefits under the Incremental Export Incentivisation Scheme for 2013-14. In Gujarat, 80 new spinning mills with a capacity of two million spindles are coming up, especially boosted by the interest subvention announced by the state government to boost industrial growth.

For four years since 2008, mills across India had been going through hard times, battling global slowdown, volatility in cotton prices and a squeeze on power availability, especially in Tamil Nadu and Andhra Pradesh. During this period about 380 mills closed down, with Tamil Nadu and Gujarat accounting for about 70 per cent of this.

This year mills expect China to import lesser yarn, which means they will have to look for alternative markets. In addition to shrinkage in the Chinese market, mills in Tamil Nadu and Andhra Pradesh will have to bear power shortage and higher tariffs this year.