Once known primarily for its traditional textile manufacturing, Shantou is rapidly becoming a shining example of digital transformation in China's textile, apparel, and fashion industry. By embracing cutting-edge technologies like 5G, AI, and advanced robotics, the city is weaving a new path towards a more efficient, sustainable, and globally competitive future.

Embracing the digital thread

Shantou's digital transformation is evident across various sectors of textile and apparel production.

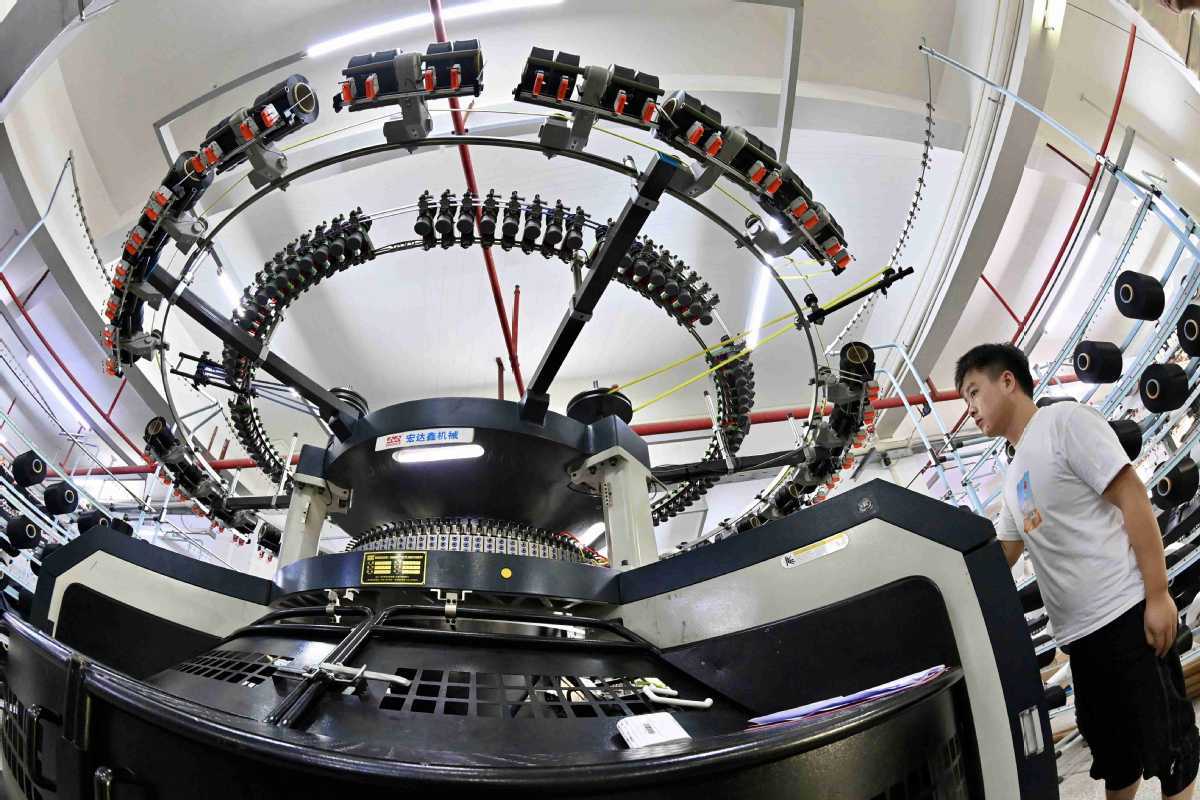

Smart manufacturing: Factories are replacing labor-intensive assembly lines with automated systems, increasing productivity and reducing errors. 5G technology enables real-time data exchange, optimizing production processes and supply chain management.

AI-powered design: Artificial intelligence is being used to analyze fashion trends, predict consumer preferences, and assist in design development, leading to faster turnaround times and more appealing products.

Digital fabric sourcing: Online platforms connect suppliers and manufacturers, streamlining fabric procurement and reducing sourcing costs.

E-commerce and digital marketing: Brands are leveraging online channels to reach wider audiences and build stronger customer relationships.

The impact of this digital shift is significant. First it has increased efficiency. Automation and data-driven decision-making have led to a reported 30 per cent increase in production efficiency in some Shantou factories. It has reduced costs. Streamlined processes and optimized resource allocation have resulted in cost savings of up to 20 per cent. Advanced manufacturing techniques and quality control systems have improved product quality, leading to higher customer satisfaction. Digital technologies are also enabling more sustainable practices, such as reduced water consumption in dyeing processes and minimized textile waste. Guangdong Gongying Information Technology (GZIT) is a leading example of Shantou's digital transformation. The company has developed multiple smart cloud platforms covering the entire textile and garment production chain. Their smart fabric sourcing platform has drastically reduced sourcing time and costs for manufacturers.

However, China's textile industry also faces challenges such as rising labor costs, environmental concerns, and increasing competition from other countries. Shantou's digital transformation offers potential solutions. It shows, automation helps mitigate the impact of rising labor costs. Digital technologies can enable more efficient resource utilization and reduced waste. And innovation and technology adoption will enhance product quality and design, boosting competitiveness in the global market.

Table: Data highlights

|

Metric |

Value |

|

Digitalization rate in Shantou's textile industry |

55.60% |

|

Percentage of smart equipment in raw material processing, weaving, and dyeing |

75% |

|

Increase in production efficiency in some factories |

30% |

|

Cost savings due to digital transformation |

Up to 20% |

A potential game-changer

Shantou's digital transformation has the potential to reshape China's textile and apparel industry. By embracing innovation and technology, the city is not only addressing current challenges but also positioning itself as a leader in the future of textile manufacturing. As other regions follow suit, China's textile industry can leverage digital transformation to enhance its global competitiveness and ensure its continued success in the ever-evolving world of fashion.