FW

The cotton sector in Zimbabwe is on the verge of collapse. Cotton contributed sustainably to rural income, development, employment and export earnings. It was the mainstay of rural communities. The sector was a major source of livelihood for over one million people, including farmers, farm workers and the textile industry as it once contributed about 19 per cent to the country’s agricultural export earnings.

However, the 2014-2015 crop season indicates that the sector is in serious trouble because many farmers have failed to access adequate inputs from contractors. Thousands of farmers have been left stranded without any input support. Cotton farmers have failed to go back to the fields arguing that contractors have reduced farmers to mere laborers and that it is no longer viable to continue producing the cash crop.

The cost of production is too high in Zimbabwe compared to other countries, while the depressed international prices have also contributed to the decline in the number of farmers producing cotton. Farmers have abandoned cotton production due to distortion in the producer price which has had a negative effect on production. Prices this year are expected to decline further as China releases its cotton stockpile on the market. Another reason is uncurbed United States subsidies.

The concept of naturally-coloured cotton is again gaining momentum with the directives of the Prime Minister’s Office (PMO) to concerned officials for promotion of coloured cotton. Taking a cue, Dharwad-based University of Agricultural Sciences (UAS) has started the mission by organising a meeting of the sub-group on this issue. It is pertinent to note that the first naturally-coloured cotton genotype of India, DDCC-1 (G. arboreum) is a significant example of genetic improvement in fibre colour and it is now under cultivation in this region. Biotechnological research at UAS Dharwad has led to substantial progress in incorporation of Bt genes into cotton genotypes of commercial importance.

D P Biradar, Vice-Chancellor, spoke about the achievements and research at the university on naturally-coloured cottons from the1990s. He stressed on the need to create new colours and mitigate the dangers of contamination due to pollen transfer which require intensive genetic engineering tools. The university had an agreement with a cotton growers’ co-operative society at Uppinabetageri in Dharwad district where seeds of coloured-cotton were given, farmers were trained and the sangha marketed the finished fabric. This activity has to be revived and the present meeting can deliberate on these issues, Biradar added.

P Nayak, Secretary, Textiles Committee, said that a synergy is required from all stakeholders in reaching a zero-defect product which is sustainable. Value-addition to the colour-cotton in terms of industry involvement and exports are being considered for funding it in a pilot project mode. According to Director at Central Institute for Cotton Research (CICR), Nagpur, Professor Kranthi, research has been going on in improving the fibre properties and yield of colour-cotton. Hybrids can also be thought of, he said.

In a detailed presentation, B M Khadi, Director of Research at UAS, said research on colour-cotton in UAS had culminated in joint ventures with co-operative societies. The first colour-cotton variety from the university recommended the release of DDCC-1. Germplasm (a term used to describe living genetic resources such as seeds or tissue, maintained for the purpose of breeding, preservation, and other research uses) with desirable traits were available at the UAS Dharwad and it can serve a network research program.

The Karnataka government has earmarked 1,000 acres for the upcoming textile park at Yadgir in north Karnataka. The government intends to also develop an integrated park at Yadgir. The state government has acquired around 3,300 acres in Yadgir district, of which about 1,000 acres will be used for setting up the textile park. The construction of the park, in the most backward region of the state, is likely to improve condition of cotton growers and weavers besides generating employment for a large number of people.

The government is also planning to develop smaller textile parks at various places such as Vijayapura, Ballari and Chamarajanagar districts. The government wants industries to move away from the congested Bengaluru region. It intends to revise its textile policy and has sought views and comments from the stakeholders of the textile industry.

The central government has come out with a scheme of integrated textile parks in the country. Till now, several proposals have come and by March this year, around seven to eight parks will be approved. State governments have been asked to come forward and identify large areas for setting up of mega textile parks. Each of these mega textile parks will be on at least 2000 acres to 5000 acres so that foreign direct investment could be attracted.

Due to a decline in domestic yarn production, India Ratings & Research (Ind-Ra) has revised cotton outlook to negative for 2015-16. It is unlikely recover in cotton exports and a fall in domestic cotton prices below minimum support prices (MSP), the rating agency said in a report here.

Factors such as contraction in domestic yarn production for exports, unlikely recovery in cotton exports, and a fall in domestic cotton prices below MSP are likely to keep domestic cotton prices under pressure in 2015-16. The conversion of China’s cotton reserve policy into a direct subsidy policy in April 2014, will increase reserve cotton sales and reduce its cotton imports to half in 2015-16. Cotton exports from India to China had fallen 26.4 per cent annually over April-October 2014, compared to a 4.3 per cent dip in the previous year, says the report.

Lower global cotton prices and the relatively stable rupee will keep the attractiveness of Indian cotton under pressure in the export market for the year 2015-16. India’s cotton exports to other destinations are unlikely to replace the quantum of lower trade with China.

Due to a drastic reduction in off-take from China, domestic cotton consumption and cotton yarn production have shown tepid growth at 3.6 per cent and 2.3 per cent, respectively, over October-November MY14-15. The agency expects cotton prices to trade lower year-on-year unless the demand of cotton yarn recovers in 2015-16.

Cotton prices (represented by Shanker-6) are likely to trade between Rs 40 per kg and Rs 45 per kg while lint prices will trade in the range of Rs 85-100 per kg for MY15-16, says the report.

Vietnam has become the biggest exporter to the United States in the Southeast Asian region with a record trade surplus of almost $25 billion in 2014, surpassing even Malaysia and Thailand. The two-way trade reached $36.3 billion, of which Vietnam exported $30.6 billion worth of goods to the US in 2014 while its imports were only $5.7 billion.

The figures show an increase of 24 per cent in export and 13.6 per cent in import compared with the previous year. Ending 2014, Vietnam enjoyed a trade surplus of $24.9 billion with the US, the highest-ever value since the two countries normalised relations.

Export of garment and textile was the main contributor in Vietnam's success with an export value of nearly $10 billion, accounting for one-third of the country’s total export value. Vietnamese textile also raised its market share in the US to 9.26 per cent.

Vietnamese textile and garment enterprises are expecting the Trans-Pacific Partnership, if ratified, will boost their exports, especially to the US as import tax will be reduced to 0 per cent from the current rates of 16 to 32 per cent. Presently, Vietnam relies to a great extent on Asian countries like China, Taiwan and South Korea for its input materials.

Union Finance Minister Arun Jaitley presented Budget 2015-16 on February 28 in Parliament. It is being touted as a major step to boost the economy, but critics feel it misses out in chalking out the real action plan and any supportive measures for the textile industry. The focus is clearly on the corporate sector which was doled out 30 percent reduction in corporate tax over the next four years. However, there is nothing to cheer the apparel and textile industry per se.

Misses industry expectations

Expressing disappointment over the reduction in TUFS allocation, Confederation of Indian Textile Industry (CITI) chairman Prem Malik said, “Payments under the scheme were pending for the last three quarters and the provision had to be doubled to disburse the pending amount. Reduction in allocation for the scheme would not encourage investment in the sector. The hike in service tax would also have an adverse impact on the textile industry.”

Experts feel Budget 2015 is disappointing for the textiles sector, because their recommendations have gone unheard. The industry had high expectations from the government’s growth oriented agenda. Being the most labour-intensive industry in the country employing over 35 million rural workers directly and contributing over 17 percent to the country’s industrial production, the sector was expecting some encouragement for improving production efficiency.

As DK Nair, Secretary General, Confederation of Indian Textile Industry says, “In view of the social and economic importance of this sector, the government has included textiles industry as an important component in the ‘Make-in-India’ program. However, with little help from the Budget, the industry will find it impossible to play its legitimate role in the country’s economic development since there is no specific mention of the textiles sector in the Budget.”

“The textiles industry has been making serious efforts to diversify into manmade fibre-based products to rectify the mismatch between global demand and domestic production in terms of fibre mix. The industry had requested for a significant reduction in the duty burden on man-made fibres in order to help this process. However, the duty burden on man-made fibres has only been hiked further in the current Budget. Apart from labour intensity, export orientation is another important feature of the textiles industry. However, the Budget has not addressed any export related issues either, for this sector,” asserts Nair.

During the interim Budget presented by Jaitley on July 10, 2014, he did not mention Punjab while announcing eight textiles mega clusters at Varanasi, Bareilly, Lucknow, Surat, Kutch, Bhagalpur, Mysore and Tamil Nadu with an investment of Rs 200 crores. Malwa region's cotton farmers and traders expected him to fulfill Prime Minister Narendra Modi’s election promise in the current Budget. However, there was no such announcement. "We were expecting a textile park in Malwa region, but the finance minister has paid no heed to formulating a policy to promote textiles. It is very disheartening. This government has done nothing to provide any relief to cotton textile industry," said Punjab Cotton Factories and Ginners Association president Bhagwan Das Bansal.

A few positives for the textile sector

A positive aspect of the Budget, as far as the textiles sector is concerned, is that the optional excise duty structure has been continued. “Considering the fragmented and highly scattered nature of this sector in the country, the industry had made a specific request that this facility should be continued until the introduction of GST. Continuation of this facility under the current Budget will help the industry to prepare for completing the procedural and logistical requirements for adapting itself to the GST framework expected to be introduced from the next fiscal,” Nair adds.

T Rajkumar, Chairman, The Southern India Mills’ Association (SIMA) welcomed the Union Budget and said, “The Budget has marked a good beginning to achieve the ‘Make in India’ vision of the Prime Minister.” He thanked the government for extending the optional Cenvat route for cotton textiles and also for the announcement of implementing GST. He, however, appealed that the Centre to reconsider certain major demands of the textile industry like removal of import duty and reduction of central excise duty on man-made fibres, allocation of adequate funds for the ongoing and all the pending cases of Technology Upgradation Fund Scheme and removal of central excise duty on shuttleless looms.

“The nine months old government has taken several long term initiatives to attract investments and create a conducive environment to make India, a hub for the manufactured goods and services. Huge plans on infrastructure developments including one lakh kilometer road, five mega power projects each with 4000 MW capacity, commencing the operation of second plant in Kudankulam Nuclear power plant, development of minor ports, plug and play approval facilities, reduction of corporate tax by 30 percent over the four years, road map for implementing GST with effect from April 1, 2016 and making EPF and ESI optional are certain measures which would facilitate and give enough confidence for investors in the manufacturing and service sectors, said K Selvaraju, Secretary General, SIMA, on a positive note.

The Indian Chamber of Commerce (ICC) and the India-Bangladesh Chamber of Commerce and Industry (IBCCI) will jointly work on the possibility of an Indo-Bangla industrial park near the border. Setting up of a joint industrial park with a thrust on textile and readymade garments would be high on the agenda of business cooperation between ICC and IBCCI.

ICC and IBCC will jointly conduct a study to identify the sectors where joint investment is possible. Bangladeshi companies are still not allowed to invest abroad because of foreign exchange constraint. Now the Bangladesh government has decided to relax this once the forex reserve reaches $25 billion. Currently, the Bangladesh forex reserve is at $23 billion.

The idea of collaboration between India and Bangladesh was mooted during the India Show organized by FICCI in Dhaka in 2012. The industry body had said that India and Bangladesh can join hands and act as a block in textile and garments. A national committee member of FICCI had also argued that India and Bangladesh can complement each other in this field.

ICC has also requested the Bangladesh government to set up a consular office in the north-east to expedite trade between the north-east and Bangladesh.

In 2014, the European Union's apparel and textile imports saw an increase of nine per cent and eight per cent respectively. Exports increased by five per cent for apparel and two per cent for textiles.

Last year, apparel imports accounted for €73.06 billion worth of goods, including €54.9 billion from Asia (10 per cent) and €14.02 billion from Mediterranean countries (five per cent). Textile imports totaled €26.4 billion euros, including €16.8 billion from Asia and €5.6 billion from the Mediterranean countries.

Apparel exports, on the other hand, accounted for €21.9 billion euros, including €5.2 billion for Asia and €1.9 billion for the Mediterranean countries. In terms of textiles, Europe reached €21.2 billion in exported goods, including €4.8 billion to Asia and €4.8 billion to the Mediterranean.

EU textile and clothing imports rose in value in 2013 following a decline in the previous year and, as a result, imports remained short of the peak reached in 2011. In volume terms, imports rose faster but remained below the levels reached during 2007-08 and 2010-11. More than 70 per cent of EU imports of textiles and clothing come from Asia. The United States is the world’s biggest textile and apparel market.

The jute industry has demanded imposition of a countervailing duty on jute imports from Bangladesh. Indian jute manufacturers have raised the demand ahead of the Union Budget to counter surging imports from Bangladesh that have grown 35 per cent in the April-December period of this fiscal.

Over the same period, domestic jute bag manufacturers cut production by more than 25 per cent. The main complaint is that there is zero duty on import of jute goods from Bangladesh, thereby creating a non-level playing field between jute manufacturers of India and Bangladesh.

The industry has also urged the government to expedite the use of jute geo-textiles in at least 15 per cent of the road construction program, as using this product in about 200 projects has been found to be beneficial and cost effective in road construction, river bank protection as well as hill slope stabilization.

Mills estimate it’s possible to reduce the cost of jute bags supplied to the government for food grain packing by as much as 30 per cent over the next two to three years through technological upgradation of jute mills and product redesigning. They say if market stability is provided by the government to the industry for sacking, jute mills would be able to increase the share of value added jute products from the current two per cent to seven to eight per cent in the next five years.

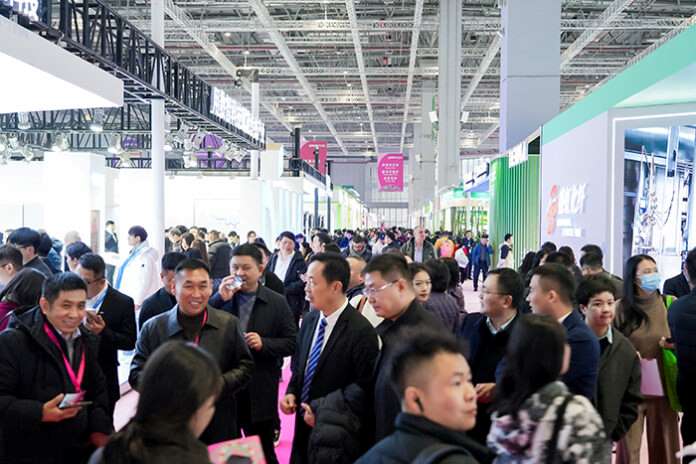

Shanghai Tex will be held from June 15 to 18, 2015. This edition will see an expansion of digital printing machinery zone showcasing latest digital printing technology and create a trendsetting direction for low carbon and a green future. Exhibitors in the zone include: Epson, Zimmer, Kornit Digital, Fujifilm, Reggiani, Toshin etc.

The three-day forum includes activities such as technical seminars, a fashion show and product showcase, where visitors may experience the business potential of digital printing from multiple perspectives. Shanghai Tex is also cooperating with Shanghai University of Engineering Science and holding a textile design contest.

Utilising latest digital printing technology, young designers’ conception and ideas will be actualized and young designers will also be able to experience power of the most advanced digital printing technology.

Digital printing has witnessed a boom in recent years. As an emerging high tech industry in the international market, digital textile printing promises extensive applications. It has an edge over traditional printing in environment-friendly production, product diversity, small batch production and product customization.

Global digital printing output is expected to reach 10 per cent of total textile printing output and the installation base for digital printing equipment will hit 50,000 machines.

www.shanghaitexonline.com/