"Stäubli presented a wide range of its latest textile machinery at its two booths at ITMA 2019. Additionally, Stäubli solutions for frame and Jacquard weaving were also seen at other booths throughout the weaving hall. Visitors to these booths learned about Stäubli’s vision for Industry 4.0 and how this development offers a chance to intensify customer and partner relationships. They also learned how Stäubli’s machinery and systems can boost their mill’s weaving performance and overall efficiency."

Stäubli presented a wide range of its latest textile machinery at its two booths at ITMA 2019. Additionally, Stäubli solutions for frame and Jacquard weaving were also seen at other booths throughout the weaving hall. Visitors to these booths learned about Stäubli’s vision for Industry 4.0 and how this development offers a chance to intensify customer and partner relationships. They also learned how Stäubli’s machinery and systems can boost their mill’s weaving performance and overall efficiency. Stäubli machinery represents a long-lasting valuable investment offering an attractive ROI due to the extended service life of the equipment, long-term spare parts availability, and swift and comprehensive worldwide service.

The major Staubli products exhibited include:

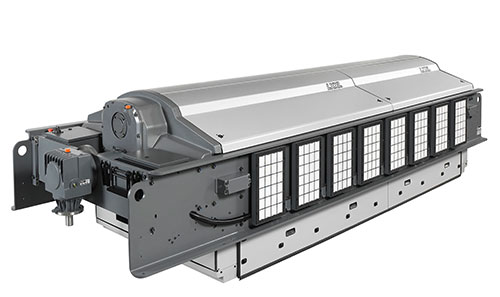

New TIEPRO warp tying machine: This new machine features extremely fine mechanical precision supported by high-performance digital technology. Weavers profit from the unique yarn separation process, the auto-reverse function, and automatic double-end detection.

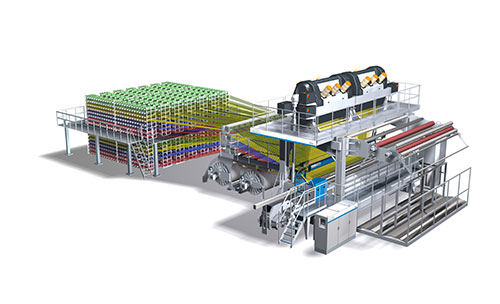

SAFIR S60 automatic drawing-in system with Active Warp Control: This exclusive yarn-repeat management system, known as AWC, is an ingenious technology that makes for more first-quality output and boosts the overall productivity of the weaving department.

New S1792 cam motion for air-jet applications: This high-speed cam motion features 10 levers and uses the new e32/e33 harness motion for even higher performance.

NOEMI: The entire LX/LXL/LXXL series of Jacquard machines for flat, terry, and velvet fabrics is now equipped with NOEMI, a new electronics concept. This compact, reliable, and suited to very large format machinery concept meets the requirements for high-speed weaving and handling the very high number of hooks to be lifted.

NEW N4L Name Selvedge Jacquard machine: This machine for name selvedge weaving offers easy positioning over the whole reed width, re-engineered quick links for quick style changes, and robust construction with Jacquard heads protected by aluminium beams. It is an ideal machine for weavers and haute couture brands to protect their valuable woven fabrics.

ALPHA 500 Series: With its Schönherr carpet systems, Stäubli showed a machine featuring two LX2493 carpet Jacquard heads, a new model of the UNIVAL 500 series of frame shedding machines handling 6 pile colors, a 4+4 weft selector, and various other interesting options. In a dedicated room, visitors observed how innovation, automation, and digitization support increased carpet output. The exhibit was completed by a carpet slider which allowed visitors to explore the many design possibilities offered by the flexibility of ALPHA machines. Visitors could also touch and feel a variety of carpet qualities, including a high-density carpet displaying a very sharp image of the Sagrada Familia cathedral with more than 4 million points/m2.

TF weaving system for technical fabrics: The Stäubli TF weaving system was set up in another dedicated area where the collection of technical carpet samples illustrated the broad range of possibilities this system offers in weaving ultra-complex fabrics.

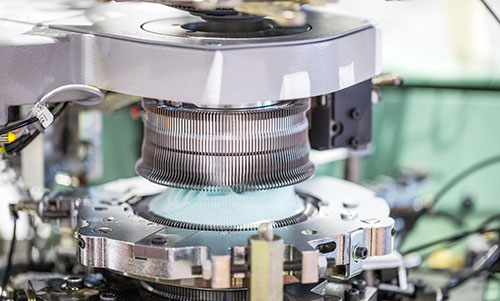

D4S automatic toe-closing device: Visitors to Stäubli’s booth in the knitting hall watched this revolutionary device rapidly sew perfectly smooth seams to close the toes of high-quality sports socks. The D4S drastically reduces sock manufacturing time.

With its two booths, Stäubli provided a broad overview of its range of solutions for future-oriented weaving mills and sock knitters. These solutions are fully in line with the company’s vision of converting high-tech mechatronics into attractive products, services, and solutions that meet customers’ requirements. Stäubli has been living out its vision of innovation for 127 years and makes its passion for fast moving technology a reality every day.