FW

Last year, fashion photographer Lisa Vogl joined department-store chain Macy's development programme, The Workshop, which helps businesses owned by women and minorities. Macy’s has now launched the Verona Collection, making it the latest company to try to capture a piece of the lucrative Muslim clothing market.

The Verona collection is now available in stores and online, along with the option of international shipping. Maxi dresses, long tops, hand-dyed hijabs, cardigans and pants are priced from US$12.95 (S$17) to US$84.95.

The collection could help Macy's sales target which has, for years, battled sluggish sales largely due to exponential rise in online discount retailers. In November, Macy revealed that sales had fallen for the 11th consecutive quarter. In 2016, it announced plans to shut around 100 stores.

Data from the latest Global Islamic Economy report states internationally consumers spent US$254 billion in 2016 on Muslim attire and estimates that the market could be valued at US$373 billion by 2022.

Luxury retailers, including Dolce & Gabbana and Burberry as well as companies that specialise in trendy casual wear, like Uniqlo, H&M and Zara have seen the writing on the wall. Last year, Nike released Pro Hijab for Muslim athletes, which is also available on Macy's website; and American Eagle offered customers a limited-edition denim hijab, which sold like hot cakes. Some of these retailers have launched collections targeted at Muslim customers who live in the Middle East and in the US.

Data from a 2014 study by the American Muslim Consumer Consortium report that of two billion Muslims worldwide, about nine million are in North America.

According to the Global Islamic Economy report, Muslim millennials are a powerful and growing economic force that will continue to transform the retail space using digital spending.

The need for speed continues to intensify with ever changing consumer trends that evolve as technology makes it possible for ideas to spread quickly – creating the demand for the see now, buy now mindset. To succeed, fashion companies need to adopt technology and embrace digitalization to streamline workflows, which enable greater agility and speed without sacrificing quality and design.

Guus Backelandt, CEO of Grosso Moda, Amsterdam says that the market evidence and conversations with the customers have helped the need for digitalization.

Often in the fashion development cycle, processes are fragmented and complex. As a longtime user of Gerber’s industry-leading AccuMark pattern design, grading, marker making and production planning software, Grosso Moda realized the strength of automating processes. Adding YuniquePLM Cloud to improve the collaboration and organization of the overall design process will help their customer better leverage data so they can focus on the needs of their consumers, ensuring they get the right products to market, at the right time.

YuniquePLM Cloud product lifecycle management software serves as a central repository of critical data and eliminates problems companies often face when using multiple Excel spreadsheets, email or tracking documents to communicate throughout the stages of product development and management. YuniquePLM Cloud creates a single version of the truth, connecting a company’s creative process with their supply chain and production processes.

Frank Heislitz will be the new Chief Executive Officer (CEO) of Freudenberg Performance Materials with effect from April 1, 2018.

Heislitz, currently CTO of Freudenberg Performance Materials, succeeds Bruce Olson, who will retire at the end of March 2018 after 11 years at Freudenberg. Bruce Olson will continue to serve as Chairman of the Shareholders' Committee of Japan Vilene Company Ltd., a joint venture between Freudenberg and Toray Industries, until the end of 2019.

Heislitz joined the Freudenberg Group in 2001 as assistant to the Management Board. In 2002, he was appointed head of the Competence Center Freudenberg Stamping and Forming Technology at Freudenberg Sealing Technologies, after that, he took over management of the Lead Center Simmerring Europe in 2005.

On January 1, John McNabb took over the role of Chief Operations Officer (COO) at Freudenberg Performance Materials from Richard Shaw, who retired at the end of 2017 after 32 years at Freudenberg. As of April 1, 2018, McNabb will take over the position of CTO of Freudenberg from Heislitz. He will be based in Weinheim.

With effect from April 1, 2018, the Management Board of Freudenberg Performance Materials will consist of three members: Frank Heislitz (CEO), John McNabb (CTO) and René Wollert (CFO).

Texfusion, an international sourcing textile show in the UK, is expected to launch a new section for denim this year.

About 150 international exhibitors and over 2500 visitors are expected to attend this edition of The London Print Design Fair (TLPDF), a leading print design show in London, and Texfusion, which will be held on March 20 and 21, 2018, in the UK.

A new hall focussing on denim is expected to be launched next month, with about 15 global manufacturers. The hall will display denim fabric, accessories and garments from international manufacturers. Among the countries presenting their wares are Spain, Pakistan, Italy, Taiwan, Thailand, and Turkey.

John Kelley, the show organiser announced, “After the launch of the garments section last March, we realised that the range of Texfusion products was not complete and something was missing. We noticed that the UK market showed an increasing attention to this product and we decided to create a denim section within Texfusion. Denim manufacturers don’t belong to any other sections and they deserve a special hall within the show.”

From March, there will also be an area dedicated to the trends for Spring/Summer 2019. Four moods will be displayed divided between fashion and technical.

The collaboration with Taiwan Textile Federation (TTF) has led to the launch of a new display area from Taiwan, where during this edition, which will focus on technical fabrics.

Ten companies from Taiwan will showcase their latest collections of functional and eco-friendly, functional non-woven fabrics, insulation, and Seawool functional fabrics and functional wool collection as well as integrated garment solutions, functional tights and leggings.

Over 1,200 fashion brands will showcase their wares at Asia's largest fashion fair, CHIC Shanghai, from March 14 to 16, 2018

China's economy is back on track after seven years recording 6.9 per cent economic growth in 2017. A recent McKinsey survey reveals that with more millionaires in China in 2018 than in any other country, by 2025, their share is expected to account for 44 per cent of purchases in the global luxury market, which is equivalent to around EUR 131 billion.

The Chinese are thus more open to spend money and this is also seen in middle to upper income groups, however what these consumers are looking for is quality over price.

Expenditure on the "key desires" in China is rising, and the supply of these goods must be increased. Tariffs on consumer goods, including those for apparel and footwear, will be lowered to make way for global brands that can offer price levels in China similar to their domestic prices.

Key drivers of consumption are China's millennials, who value authenticity, individuality and sustainability.

The desire for individual offers and collections is on top of the mind by CHIC also the retail sector, which focuses on lifestyle concepts and exclusive and creative brands. Multi-brand stores and boutiques have become co-operation partners of CHIC.

CHIC provides valuable input on current fashion trends in China thus over 15 Chinese and international brands will take centre stage at Asia's leading fashion and lifestyle fair. As part of the CHIC Talk, market experts and trend analysts will discuss current developments in the fashion business in China, both for offline and online business.

American fashion retailer American Eagle Outfitters is expected to shut shop in the Singapore market at the end of the month with the closure of its two stores here it was reported.

The store is currently having a closing-down sale and industry watchers said that its closure on Feb 28 will be the final day of operations here. Its Vivo City store shut shop on Wednesday.

American Eagle Outfitters had launched operations here around three years ago under domestic firm Star 360 Holdings, which gained exclusive retail and distribution rights for the brand in Singapore and Malaysia. Star 360 also retails brands such as Onitsuka Tiger, Birkenstock and Cole Haan here along with its multi-label footwear and apparel stores.

Recently fashion retailer FJ Benjamin announced the closure of Gap and Banana Republic stores here by the end of February.

Ms Esther Ho, deputy director of Nanyang Polytechnic's School of Business Management, assessed that the rise of fast fashion labels such as H&M, Zara and Forever 21 has hurt brands like Gap and American Eagle Outfitters which retail at a slightly higher price point and do not produce new styles as the market demands. "For American brands, the growth of e-commerce also affects how their stores perform here. Singaporeans can bypass the distributors and buy direct online instead," she added.

Iconic French lingerie brand, Simone Perele, celebrates its 70th anniversary in 2018 and will be launching its 1948 collection.

In 1948 Madame Perele set up a small workshop in Paris and her working credo, ahead of its time, was “in order to reveal a woman’s beauty, we must liberate women’s bodies.” The contemporary offer recreates traditional styles from the late Madame Perele: from beautiful satin corsets with elegant top-stitched branding along the neckline to stunning edgy bustiers that accentuate women’s curves.

Simone Perele is renowned as one of the leading manufacturers of fine French lingerie. Every collection is inspired by art, travel and culture. The brand is available in over 120 independent retailers and department stores throughout the UK & Ireland.

The 9th Asian Textile Conference (Atexcon) will be held on on 14th March 2018 at Hotel ITC Maratha.

Honorable Union Minister for Textiles and Information and Broadcasting, Smriti Zubin Irani government of India has kindly agreed to inaugurate and address the 9th ATEXCON. Other senior government officials, policy makers and trade experts from ministries of textiles, finance, commerce, etc. and related departments are also invited to deliberate on important policy aspects.

Through its successful endeavors in the past, ATEXCON is now identified as a recognized and important platform for discussing major trends shaping the global textile and apparel industry. Since the event consists of panel discussions.

Considering the importance of this conference, we invite you to attend the 9th ATEXCON. There is no participation fee to attend the conference but participation will be regulated by invitations.

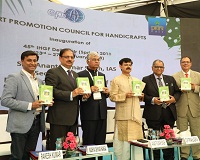

Anant Kumar Singh, Secretary [ Textiles], Ministry of Textiles inaugurated the 45th edition of world largest handicraft and gifts fair known world over as IHGF-Delhi Fair today.

The fair is being held from 23rd to 27th February, 2018 at state-of-the art India Expo Centre, Greater Noida.

Anant Kumar Singh said “Handicrafts sector plays a significant and important role in the country’s economy. It provides employment to a vast segment of craft persons in rural and semi urban areas and generates substantial foreign exchange for the country while preserving its cultural heritage.”

He further elaborated that the Ministry of Textiles has implemented various projects to provide assistance to craft persons and exporters. The growth in exports ultimately results in generation of employment in this decentralised sector of the economy and improve their living standards.

The Secretary shared his experience during his visit to Ambiente 2018 in Frankfurt that he found that products displayed there by over 400 handicrafts exporters were not less than the best in the world and noted that Messe Frankfurt has declared India as a partner country for Ambiente 2019.

O.P. Prahladka, Chairman – EPCH said that The Handicrafts exports during the year 2016-17 was Rs.24,392.39 crores with overall 13.15 per cent increase as against last year. However, the exports of handicrafts during 10 months of the current fiscal 2017-18 is Rs.19,862.19 crore.

EPCHs Chairman further elaborated that 14 product categories of house ware, home furnishing, furniture, gifts and decoratives, lamps and lighting, Christmas and festive décor, fashion jewellery and accessories, spa and wellness, carpets and rugs, bathroom and garden accessories, educational toys and games, handmade paper products and stationery and leather bags was the USP of 2000 styles showcased under one roof by Indian exporters.

Rakesh Kumar, Executive Director – EPCH revealed that overseas buyers from over 103 countries worldwide is visiting the five days extravaganza. He disclosed that EPCH in its efforts to bring hidden treasures from different craft clusters, have set up theme pavilions of products from Jammu & Kashmir, the North Eastern Region and Jodhpur during the show.

Most often cheaper quality cotton is passed off as Egyptian or Pima cotton despite the fact that they are labelled as 100 per cent pure cotton. Now, American Pima growers have found a solution. Supima, the not for profit marketing organisation that represents American Pima growers, has partnered with Oritain Global to provide testing to identify and verify the origin of Supima cotton, which is Pima cotton grown by licensed Supima-cotton companies.

Jason Thompson, Brand Development Manager, says they have been trying to find different solutions for the last 10 years. When a product bears the Supima trademark, they want to ensure the cotton is verified. Oritain will use scientific technology to measure the naturally occurring elements that exist within the cotton fibre, which is based on the geographical production area where the cotton is grown.

Grant Cochrane, Chief Executive of Oritain explains the unique fingerprint analysis identifies different levels of chemical attributes that are found in the product itself and enables the cotton to be verified against its claimed origin. The identification process is done by mapping the geographical region where the cotton is grown and identifying the trace elements in the soil, water and air.

About 85 per cent of the American Pima cotton grown in the US comes from California and the balance from Arizona, New Mexico and Texas. There are over 500 American Pima growers in the US whose extra-long-staple cotton sells for twice as any other US cotton.The advantage of the Oritain method is that it doesn’t need to apply any identifiers or tracers during the manufacturing or processing phases, which makes it a simple solution that measures what is naturally found in the fibre.