FW

Three leading Hong Kong fashion designer labels will take part in the Fashion Hong Kong runway show, organised by the Hong Kong Trade Development Council (HKTDC), at New York Fashion Week February 2019, showcasing Hong Kong's fashion creativity to industry elites and style influencers from the United States and around the world.

Launching their fall/winter 2019 collections at the runway show on February 8 will be Annette Chan of the brand Anveglosa and the design duo Yi Chan and Lary Cheung of the brand Heaven Please, who return to the show for the second consecutive year, as well as Mountain Yam.

An after-show party will be held for the designers to network with industry players. Since 2015, Fashion Hong Kong has been staging world-class runway shows at major international fashion events, including New York Fashion Week, London Fashion Week, Copenhagen Fashion Week and Tokyo Fashion Week, to showcase Hong Kong's fashion design prowess in overseas markets.

Fashion Hong Kong is a series of international promotions organised by the HKTDC to raise the global profile of Hong Kong fashion designers and labels. To maximise exposure for Hong Kong fashion brands during their time in New York, Fashion Hong Kong will take part in Coterie - the premier global event and trade platform for contemporary fashion brands in New York - for the first time.

The global textile auxiliaries market is set to get a boost with a surge in consumption and production of textiles. Textile auxiliaries are used at various stages of textile processing like pre-treatment, printing, dying, and finishing. Textile auxiliaries increase the aesthetic appeal as well as the durability of textile products.

Textile auxiliaries are mainly used for architectural and construction purposes like concrete reinforcement, insulation, and faced foundation. The growth in infrastructure and urbanization on a rapid scale in Brazil, Russia, India, China, and South America is providing an advantageous factor for the development of textile auxiliaries in the global market.

Demand for healthcare products like sanitary napkins and baby diapers are also fuelling the growth of the textile auxiliaries market in the world. However, factors like high cost of natural textile auxiliaries may hamper growth in the long run. Natural textiles are more expensive as compared to synthetic and this is because of the high cost of raw materials and limited availability in terms of natural auxiliaries. Manufacturing and extraction of natural textile auxiliaries require trained workers with technical knowledge. Factors like these may affect the development of the textile auxiliaries market in the long run.

Bangladesh’s apparel exports to the UK from July to December grew only 1.30 per cent. Uncertainty over Britain’s exit from the European Union has made apparel importers in the UK conservative in placing work orders.

However, the UK has committed to providing Bangladesh duty and quota-free market access even after the execution of Brexit. The UK is the third largest market for Bangladesh’s goods. Garments account for more than 80 per cent of Bangladesh’s total exports to the UK. A large number of non-resident Bangladeshis live in the UK.

In a referendum held on June 23, 52 per cent of people in the UK wanted to leave the EU and 48 per cent voted to stay with the union. In the first half of the fiscal year 2017-18, Bangladesh’s apparel exports to Britain saw a 20.70 per cent growth. On the other hand, in fiscal year 2017-18, export growth to the UK was 12.63 per cent. In the July-December period of the current fiscal year, 2018-19, Bangladesh’s earnings were up by 15.65 per cent. Brexit anxiety has also hit the economy of the UK. Economic slowdown in that country, caused by slower job growth and GDP growth, has cut demand for goods.

Shima Seiki together with its Italian subsidiary, Shima Seiki Italia, will participate at ISPO Munich 2019, in hall b4, booth BN05. The world’s largest trade fair for sports equipment and fashion will be held from February 3-6, 2019. Shima Seiki, based in Wakayama, Japan, is a leading manufacturer in the computerised flatbed knitting machine industry.

The company will be a corporate partner to the ISPO Brandnew Village, a special platform for promising newcomers to the sports industry.

On display in Brandnew Village will be the stateoftheart SVR123SP computerised knitting machine that features a special loop presser bed, capable of producing hybrid inlay fabrics with both knit and weave characteristics. Demand for such novel fabrics are very high across a wide range of applications including sportswear, innerwear, outerwear, uniforms, and other functional clothing, as well as home furnishing and technical textiles. SVR123SP at ISPO Munich furthermore will feature the new iPlating option, capable of alternating yarn colours in any pattern, producing jacquardlike designs using plain jersey stitch. With iPlating, plating can be performed within the same course and for individual needles for even greater diversity in knit design. The latest sportswear samples produced on SVR123SP will also be on display, as well as revolutionary seamfree Wholegarment knitwear that feature superior fit, comfort, and style that are ideal for sportswear, according to Shima Seiki.

The latest version of Shima Seiki’s 3D design system SDS-ONE APEX3 will also be exhibited. At the core of the company’s “Total Fashion System” concept, APEX3 provides comprehensive support throughout the product supply chain, integrating production into one smooth and efficient workflow from yarn development, product planning and design to production and even sales promotion. Especially effective is the way APEX3 improves on the design evaluation process with its ultrarealistic simulation capability, whereby virtual samples minimise the need for actual samplemaking. This realises significant savings in time, cost and material, contributing to sustainable manufacturing.

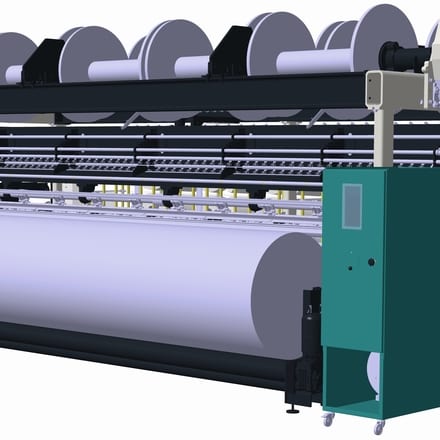

The new TM WEFT for the standard segment is complementing the WEFTTRONIC® II HKS for the premium segment

KARL MAYER is transferring its successful two product line strategy to its Technical Textiles Business Unit and is supplementing its premium weft-insertion machine with a standard model. In addition to the WEFTTRONIC® II HKS, there will also be a TM WEFT in future. This new warp knitting machine with weft-insertion facility bears all the hallmarks of the high-end version in terms of its quality and reliability, but its optimised cost:benefit ratio targets a different market.

The right machine for every market segment

This new machine is a machine from Asia for Asia. “Our target market is China and the mid-range segment in particular”, explains Hagen Lotzmann, the Sales Manager of KARL MAYER Technische Textilien GmbH. To score points here, the TM WEFT delivers a 50% higher cost:benefit ratio than the WEFTTRONIC® II HKS. The considerable increase in speed has been achieved by completely redeveloping the machine and modifying the production logistics. The engineering know-how and the core areas of expertise for the TM WEFT are being provided by locations in Germany, and all the other work is being done by KARL MAYER (CHINA). This has led to the exceptional quality and operating reliability typical of all KARL MAYER’s machines, and also delivers an attractive performance package for producers of standard goods for the interlining market. With its fine gauge, the WEFTTRONIC® II HKS is still the number one machine for producing fine interlinings and high-quality automotive textiles, for use in e.g. sun protection.

Customised technical features

The TM WEFT is available in a gauge of E 24 and a working width of 247", which can be reduced by 62". Its features include two stitch-forming ground guide bars, the KAMCOS®2 Single Speed and integrated Laserstop facility for the early detection of yarn breakages. Up to 24 wefts can be inserted at the same time during production. The yarn is delivered from a creel with yarn storage feeders. An electronically controlled, 4-roller system is responsible for fabric take-down, and the fabric is wound by stand-alone batching unit no. 64. It has friction drive, with control in line with the stitches.

An eagerly anticipated sales release

The TM WEFT was announced at ITMA ASIA + CITME 2018 in Shanghai and proved to be a hot topic of conversation. “Our customers are extremely interested in our new weft-insertion warp knitting machine, and are already looking forward to the official market release,” says Hagen Lotzmann. This sales expert is expecting that the first orders for this standard model, with its excellent cost:benefit ratio, will be placed this year. The sales release is scheduled for the second half of January 2019. An in-house show will also be held in January at KARL MAYER (CHINA) in Changzhou, where the TM WEFT will be demonstrating its features.

LONG BEACH, Calif.—Customization is on the rise.

LONG BEACH, Calif.—Customization is on the rise.

That was the message at the Imprinted Sportswear Show, where exhibits pointed to the trend where consumers increasingly seek to shape the cuts and styles of their clothes.

The annual Southern California show, which ran Jan. 18–20 at the Long Beach Convention Center, is a sprawling event for T-shirt blanks, hoodies and embroideries, as well as for machinery to screen-print graphics on clothing.

The trade show this year covered 115,000 square feet of the convention-center floor while last year it encompassed 111,000 square feet, said Joshua Carruth, a trade-show director for Emerald Expositions, which owns ISS.

Attendance at this year’s show was basically even with last year’s show, which is frequented by printers, decorators, brand executives and people starting new brands.

For the past couple of years, designers have shopped ISS to find out which tech company could help them produce small runs of clothing for a market interested in customization. For this year’s show, the topic of customization gathered more momentum.

of clothing for a market interested in customization. For this year’s show, the topic of customization gathered more momentum.

“Everything is about customization,” said Michael Sanders of True Value Fabrics, a textile supplier headquartered in Carson, Calif. “This used to be a show about blanks. Now it’s more of a digital show.”

Steve Nanino, president of the Los Angeles–based Kid Dangerous, which makes small runs of clothing as well as third-party brands, said that even though there are more digital printers around, he didn’t expect them to take over the industry.

“People are interested in digital printers. But they are inherently slower and more expensive than screen-printing. Until the digital side is able to get better, there is still a role for screen-printing. The biggest hurdle for digital is speeding up,” Nanino said. Many screen-printers have an advantage of offering quick return, he said.

ISS embraced that both technologies can co-exist. Show management exhibited an installation called the Innovation Zone, which documented the journey of a garment through a production cycle and featured both digital and screen-printing machines.

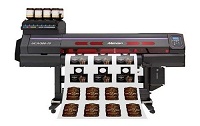

Israeli-headquartered Kornit Digital unveiled the Atlas print system at the show. The direct-to-garment printer includes a new ink set called Eco-Rapid, which offers more colors and is more durable. The machine introduces an intelligent-user interface to support self-service.

Also at the show, Irvine, Calif.–headquartered Roland DGA released the VersaSTUDIO BT-12. It’s a direct-to-garment desktop printer made for printing directly onto cotton products.

Also at the show, Irvine, Calif.–headquartered Roland DGA released the VersaSTUDIO BT-12. It’s a direct-to-garment desktop printer made for printing directly onto cotton products.

Technology company Epson displayed products such as its direct-to-garment polyester pretreatment. Tim Check of Epson America Inc. in Long Beach said the pretreatment solution was similar to putting a coat of primer on a wall. It ensures digital prints stick to polyester.

Danvers, Mass.–based company Inkcups exhibited a Brite Tagless printer, which is designed for printing highly opaque, white-colored inks on dark fabrics.

Making small runs of clothing was stressed at some brands displaying tees and blanks. Bayside Apparel showed garment-dyed crew-neck T-shirts, which could be produced at a run of 100 shirts at a time, said Jessica Escobedo, a brand representative.

A myriad of looks and styles of blanks was displayed at the show. At the Los Angeles Apparel booth, brand founder Dov Charney exhibited blanks made from coarser threads, which produce heavier T-shirts. It was a change from the lighter, fitted blank that was popular at American Apparel, Charney’s previous company.

Champion, a division of Hanes Brands, celebrated the 100th anniversary of Champion by reissuing some of its most popular looks from past years but with new fabrics. Looks included ringer tees and three-quarter-sleeve baseball tees.

Gildan released a polo shirt that wicks away sweat. Jeff Cooper, Gildan’s vice president of marketing, described the garment as a polo made with performance fabrics. The company also released new colors for its fleece program, including azalea, mint green, orchid and violet.

Downtown Los Angeles–headquartered Blanks Plus showed its Moco brand. The line of T-shirts, manufactured in Los Angeles, is made with MicroModal fabric and the company’s Eco-Hybrid fabric.

Irwindale, Calif.–headquartered Lane Seven Apparel exhibited its new, heavyweight pullover hoodie. Los Angeles–based Next Level Apparel displayed a new line of relaxed women’s tops.

While all sorts of styles of tees were offered, heavy, box-shaped T-shirts were en vogue, said Justin Bautista, co-owner of Tilted Brim, a San Francisco boutique. “T-shirts with extended hems have come and gone,” he said.

Popular graphic styles included big logos on the back of T-shirts, as well as chest hits and a graphic on the top left-hand side of the chest, he said.

Cotton Heritage, headquartered in Commerce, Calif., offered new categories including a women’s line of pullovers, zip hoodies and jogger pants. Previously, Cotton Heritage only produced unisex hoodies and jogger pants. “They will be better-fitting garments,” said Ken White, Cotton Heritage’s vice president of sales. The brand also introduced new garment colors including artichoke, dusty rose, agave green, shale blue and antique gold.

Business was good at ISS, White said. “It was well attended. There were great meetings with customers and potential customers. We worked with screen-printers who we have worked with for a long time. We saw a lot of brands looking for new blanks. They were looking for new colors and new silhouettes,” he said.

Mimaki will introduce its latest dye sublimation printer, Mimaki TS55-1800, at the Salon C!Print show in Lyon to be held from February 5-7, 2019. TS55-1800 is ideal for interior fabrics, sports and fashion apparel, flags and tapestries. Offering continuous operation, this printer is designed for users that demand high productivity and high-quality print.

Mimaki will introduce its latest dye sublimation printer, Mimaki TS55-1800, at the Salon C!Print show in Lyon to be held from February 5-7, 2019. TS55-1800 is ideal for interior fabrics, sports and fashion apparel, flags and tapestries. Offering continuous operation, this printer is designed for users that demand high productivity and high-quality print.

Mimaki will also showcase the extensive business-enhancing applications possible with its range of sign graphics, industrial products, textiles and apparel printers, and participate, as a partner, in the show’s plug and play area. A space dedicated to trends, innovation and experimentation, Mimaki’s small format LED UV UJF-MKII printer will enable visitors to personalise their own products, envision their latest campaign or opt for something more personal, said a press release from the company.

With a literal interpretation of its show theme ‘Join the Experience’, this year, Mimaki Europe has invited Salon C!Print visitors to participate in its celebrations of Mimaki France’s 10th anniversary throughout the show.

“Our aim is to inspire visitors at C!Print with applications that are relevant to them and their businesses, but also stimulate new ideas. Mimaki has an incredibly comprehensive range of printers so there’s something there to suit all requirements,” said Danna Drion, marketing manager, Mimaki Europe. “From our unique four-layer technology for backlit signage to five-layer printing for printing on both sides of a transparent substrate, to various promotional items, and home décor, Mimaki really does have something for everyone.”

“We’re also taking time at the show to mark the ten-year milestone since we established our Mimaki France office in Paris. The facility represents Mimaki’s ongoing commitment to the French market and a determination to ensure each market is supported with first-rate local service. Mimaki is not only a specialist in added value technology, but in customer support too. We’re keen to celebrate that,” concluded Drion.

Roland DG Corporation launched the VersaSTUDIO BT-12 desktop direct-to-garment printer for printing directly on cotton-based products. Built for on-demand personalization, the BT-12, which will be available from April 2019, is ideal for businesses looking for new revenue opportunities by offering an engaging in-store experience for their customers.

The BT-12 is an A4 size printer that prints full color graphics including photos, logos and text directly on a wide variety of cotton-based items, such as t-shirts, tote bags and textile interior decoration products. Its compact size and affordable price enables businesses to offer personalization services with a low initial investment and in locations where space is limited, including shopping malls, kiosks, apparel stores, hotel gift shops and tourist destinations, and at events.

“Consumer behavior has been shifting from consumption to experience due to the diversification of consumer values,” Etsuo Harada, division president of COTO Business Division for Roland DG, said. “As a result, businesses have an opportunity to offer high-value merchandise such as personalized products to meet customer needs and desires.”

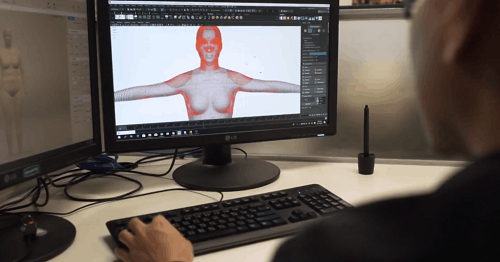

The Alvanon Body Platform (ABP) is a cloud database of over 6,000 virtual bodies designed for hundreds of fashion and retail brands globally. These bodies will be easily accessible by brands and their authorized vendors for a seamless transition into the digital supply chain

NEW YORK – January 22nd, 2019 – The apparel-technology company Alvanon, is taking the use of 3D digital design to the next level with the launch of the Alvanon Body Platform (ABP). ABP is a new and secure cloud database offering 3D fit standards for the global apparel industry. For the first time, ABP will enable apparel design and development teams to access Alvanon’s vast library of over 6,000 virtual AlvaForms (3D avatars). Operating on all collaborating 3D software systems*, ABP will provide a fast, accurate and consistent way for brands and retailers to access and share their 3D fit and core body standards with their supply chain partners. The virtual 3D AlvaForms represent the dominant body shapes and sizes of consumers across the globe and offer exceptional design and development features including virtual texture and measurement lines; flexible poses; and a high-resolution 3D mesh to facilitate draping functionality.

NEW YORK – January 22nd, 2019 – The apparel-technology company Alvanon, is taking the use of 3D digital design to the next level with the launch of the Alvanon Body Platform (ABP). ABP is a new and secure cloud database offering 3D fit standards for the global apparel industry. For the first time, ABP will enable apparel design and development teams to access Alvanon’s vast library of over 6,000 virtual AlvaForms (3D avatars). Operating on all collaborating 3D software systems*, ABP will provide a fast, accurate and consistent way for brands and retailers to access and share their 3D fit and core body standards with their supply chain partners. The virtual 3D AlvaForms represent the dominant body shapes and sizes of consumers across the globe and offer exceptional design and development features including virtual texture and measurement lines; flexible poses; and a high-resolution 3D mesh to facilitate draping functionality.

“At Alvanon, we believe that the 3D journey begins with the avatar. Not just any avatar, but the fit standard that represents the brand’s target customers’ body shapes and sizes,” explained Jason Wang, chief operating officer, Alvanon. “In recent years, we’ve seen a huge increase for client bodies in the form of 3D virtual AlvaForms. The Alvanon Body Platform has been developed by our technology teams to specifically meet the fashion industry’s 3D digital design needs. Through collaboration with major 3D software companies, we have developed a seamless and secure digital avatar while providing the fit accuracy that brands and retailers require.”

Stephen Sze, director of software engineering, Alvanon concluded: “This is just the beginning for the virtual AlvaForm. This launch marks a new era for retail innovation – the use of 3D digital design allows brands to create realistic prototypes in a variety of different styles without having to actually make them: eliminating huge amounts of waste each year. ABP is the starting point for that 3D journey.”

Alvanon’s R&D team invited a select group of apparel professionals throughout the fashion industry including such brands as American Eagle Outfitters, Express, J.Crew, Kohl’s, Lucky Brands, Lululemon, Napapijri, Talbots and Under Armour, to beta test the platform and user experience.

To learn more or get set up with your ABP account today visit abp.alvanon.com

*The Alvanon Body Platform at launch supports CLO and Browzwear 3D softwares with Optitex, SHIMA SEIKI, TORAY ACS, TG3D Studio and more available in 2019.

About Alvanon

Alvanon is a global technology company, focused on the body and its application and implications in the apparel industry. We don’t make clothes, we help brands make clothes fit better, have efficient and sustainable processes, and train their people better. We are the science behind the art of fit.

Since 2001, we have dedicated ourselves to body data research and have gathered more than 1.5 million body scans in over 30 countries. Combined with our deep apparel knowledge, this has allowed us to develop thousands of fit standards for hundreds of brands globally. www.alvanon.com

About The Alvanon Body Platform

The Alvanon Body Platform (ABP) is an ever-growing cloud database of over 6,000+ Virtual AlvaForms (3D avatars) designed for hundreds of brands globally. The ABP platform will be easily accessible and encrypted, facilitating a secure and seamless process by which vendors can access brand’s 3D fit standards and size sets in most 3D software formats. The ABP Platform is a response to the industry’s need for a digital, 3D solution that cuts costs and increases speed-to-market. It virtually replicates the costly process of physical fitting.

Moreover, those who want to set-up new units with latest technology would have to import machineries from countries like China, Germany and other countries which is much more costlier than traditional or obsolete machineries.

With textile machineries and equipment becoming expensive, coupled with over dependence on import, would make entry of new entrants in the segment more difficult.”

With textile machineries and equipment becoming expensive, coupled with over dependence on import, would make entry of new entrants in the segment more difficult.”

Increasing cost of machinery in textile value chain is discouraging newcomers, especially MSMEs from entering the textile sector in Gujarat. This is despite the state government’s recent initiatives to encourage investment. Right from manufacturing of yarn to weaving, processing and even garment manufacturing require sizeable investments. Moreover, those who want to set-up new units with latest technology would have to import machineries from countries like China, Germany and other countries which is much more costlier than traditional or obsolete machineries.

Devkishan Mangani, chairman of textile trade committee, South Gujarat Chamber of Commerce, says that in case of powerlooms, entrepreneurs earlier were able to start business with couple of lakh rupees by purchasing 3-4 traditional machines. However, today a single power-loom would cost up to `50 lakhs. Hence, it would be out of reach for micro and small businesses. Even medium size businessmen are feeling the pinch as setting-up a textile unit earlier used to cost around `10-12 crore, but now with the cutting-edge technology, the cost would easily cross `100 crores, adds Mangani.

In order to strengthen textile sector, Gujarat government has given plethora of sops, but mostly for existing units. The new policy, announced ahead of Vibrant Gujarat Summit, tried to address issues ranging from technology upgradation, forward-backward integration, setting up textile parks, power subsidy and others. However, the policy doesn’t have much for the new textile units.

Requesting anonymity, a senior official in the state industries department informed that even in the recently concluded summit, most of the MoUs inked in textile sector were related to expansion of existing units. Most of the MoUs were done by big textile players. Those in the MSME segment would have a real challenge to implement the project with limited financial resources, he said. Unless micro and small units wouldn’t become part of textile value chain of the state, textile industry would not generate adequate jobs, says the official.

In Gujarat, garment manufacturing is limited to handful of big players, says textile expert Chandan Chatterjee, adding, “Garment manufacturing is the driving force for entire textile value chain. Unlike Tirupur, where MSMEs are thriving in ready-made cloths, Gujarat is lacking a proper ecosystem. With textile machineries and equipment becoming expensive, coupled with over dependence on import, would make entry of new entrants in the segment more difficult.”

According to Meena Kaviya, textile committee co-chairperson of Gujarat Chamber of Commerce and Industries (GCCI), sizeable capital subsidy on machinery would be required in order to make a new unit affordable. Kaviya believes that the state government shouldn’t have imposed a cap of `30 lakh for extending assistance for the cost of machinery and equipment required for environment compliance as well as for the conservation of energy energy and water.