FW

Lenzing Group has set a target to achieve climate neutrality by 2025. The group recently commissioned a new air purification and sulfur recovery plant at its facility. The plant has been developed with an investment of €40 million and it uses state-of-the-art technologies to reduce carbon emissions by 15,000 metric tons at the Lenzing facility. This will also make the group more self-sufficient in securing vital raw materials for processing, which will bolster the site’s competitive standing in terms of sustainability.

The Lenzing Group is an ecologically responsible producer of specialty fibers made from the renewable raw material wood. As an innovation leader, Lenzing is a partner of global textile and nonwoven manufacturers and drives many new technological developments. The Lenzing Group’s high-quality fibers form the basis for a variety of textile applications ranging from elegant ladies clothing to versatile denims and high-performance sports clothing. Due to their consistent high quality, their biodegradability and compostability Lenzing fibers are also highly suitable for hygiene products and agricultural applications.

Vinnova, the Swedish government’s research and development agency, and IVL, the Swedish Institute for environmental research have opened the world’s first fully automated textile sorting plant in Sweden. The plant is being designed and built by Stadler and Tamara as a part of the SIPTex project. This is the third phase of the project which began with the start-up of the fully automated sorting plant Sysav Industry AB in Malmö. The plant has a capacity of upto 4.5 ton/hour in one line. The incoming material is delivered in bales comprising pre-and post-consumer textile waste, i.e. industrial waste such as cuttings, yarns, and scrap, and used domestic clothing and textiles.

In the third phase, the project aims to ascertain that the system can all be sorted and separated by type and quality. The company also aimed to determine if it could successfully operate on an industrial scale, and the output fractions can achieve the purity and recovery required for recycling and reutilization also there is no industrial-scale technology for recycling textiles without down-cycling them.

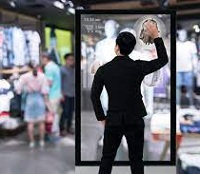

Physical retail went through a huge transformation last year due to the pandemic. As per Euromonitor International estimate, the world lost around 135 million sq mt of selling space as 1.7 million retailers closed stores. The analyst expects in-store shopping to further reduce to 76 per cent by 2025 from 81 per cent in 2020.

Physical retail went through a huge transformation last year due to the pandemic. As per Euromonitor International estimate, the world lost around 135 million sq mt of selling space as 1.7 million retailers closed stores. The analyst expects in-store shopping to further reduce to 76 per cent by 2025 from 81 per cent in 2020.

Change in store sizes and locations

Around 5 per cent of non-grocery retail stores in Western Europe and North America closed permanently last year. Global retailer Inditex plans to close 1,200 stores globally by 2022 to focus on larger flagship outlets while Coffee giant Starbucks aims to shut around 800 stores in dense metro centres.

High street retailers are also changing their store locations and formats. UK-based retailer Harrods is moving into the surburbs by launching its f H Beauty outlet at Intu Lakeside in Essex. The retailer plans to launch another store at Intu in Milton Keynes.

outlet at Intu Lakeside in Essex. The retailer plans to launch another store at Intu in Milton Keynes.

Emergence of new store concepts

Retailers are also experimenting with new store formats like pop-ups, store-within-a-store and mobile or ‘shop-on-wheels.’ Jewellery brand Swarovski opened 28 temporary Instant Wonder stores in 2021. The first of these instant Wonder pop-ups was launched in Milan in February 2021. It provided consumers with a more premium multi-sensory shopping experience.

Popups like these are likely to gain more popularity as they help retailers create brand-focused and experience-led spaces besides allowing them to sign more flexible, short-term lease agreements. An innovative store concept set to officially launch in Spring 2021, Grocery Neighbor is designed in the form of a truck with two doors, The concept enables retailers to create a mobile grocery stores for consumers.

According to an Euromonitor International survey, the store concept benefits consumers working from home post pandemic, and older consumers’ hesitating to return to supermarkets or convenience stores .Grocery Neighbor aims to expand the store concept to 1,000 trucks outside Toronto within the next five years.

Re-examining retail strategies

Retailers are also converting stores into warehouses or micro fulfillment centres. Spanish retailer El Corte Ingles has converted a Bricor DIY store into warehouse to fulfill online food orders in just 10 days. Such local micro-fulfilment centres are likely to gain more popularity with Walmart planning to roll out local fulfilment centres at dozens of stores in the US in 2021.

Moving forward, retailers will need to re-examine the size, location and role of their stores. They would have to redesign these stores to play multiple roles as fulfillment centres and engagement areas. They would also have to adopt an omnichannel strategy to tap consumers from smaller cities.

Revenues of all major fashion companies such as Minor Group, the marketer of Esprit, Bossini, Charles & Keith and Anello brands; ICC International Plc, the marketer of Arrow and Guy Laroche; and Greyhound Co, the marketer of Greyhound and Smileyhound by Greyhound lifestyle fashion brands, have fallen by an average of 20 per cent.

DhitibhumWongkiatkachorn, Marketing and Business Development Director, Greyhound Co, says, the company’s online sales are also suffering compared to the first outbreak last year because of weakened consumer confidence. Greyhound believes the tepid market sentiment will continue until the third quarter this year. As a result, the company is postponing the launch of new sporting product lines for its two fashion brands, Greyhound and Smileyhound, as well as a new fashion brand until the fourth quarter this year. However, the firm has expedited the launch of its sales campaign for its summer collection by two to three months, running from May to June 30 this year.

Minor Group’s retail trading business (MINT) in the first three months this year dropped by 31 per cent to 473 million baht, mainly due to weak consumer spending in the fashion business, the temporary closures of some stores and the slowdown of the tourism sector amid COVID-19.

At the end of the first quarter of this year, MINT reported the number of its shops dropped to 428, down from 473 in the same quarter last year, primarily from the closing of the OVS and Etam brands. Of the total 428 retail trading outlets, 77 per cent are operated under fashion brands, including Anello, Bossini, Charles & Keith, Esprit and Radley, while 23% are operated under lifestyle brands including Joseph Joseph, Zwilling J.A. Henckels, Bodum and Scomadi.

According to Chaiyapat Paitoon, MINT's chief strategy officer, non-essential spending could be suspended from 2020-2022 as the group focuses on the hotel and food businesses.

Thammarat Chokwatana, Executive Vice-President, ICC International, said, the company plans to focus on promoting potential brands and explore new channels to drive sales

Retailer C&A is building a factory to manufacture denim jeans in Mönchengladbach, Germany.

As per reports, the factory will produce 400,000 jeans per year, later doubling to 800,000.

C&A will work with Niederrhein University of Applied Sciences, the Textile Academy NRW and RWTH Aachen University on the project, incorporating highly automated sewing and laundry processes.

The Factory for Innovation in Textiles (FIT) will set new standards in textile production, according to C&A.

Rolf Königs, Chairman, Rheinische Textile and Clothing Industry Association, says, this investment by C&A underlines that the textile industry in the middle of Europe is back. First jeans from the factory will be available next year.

In 2018, C&A worked with mill Rajby to develop the first jeans with the Cradle-to-Cradle Gold level certification. In 2020, its Beluga jeans were awarded with a platinum award.

According to Lanka Raghurami Reddy, President, AP Textile Mills Association, spinning mills in Andhra Pradesh have reduced 40 per cent of their cotton production due to COVID -19 and workers shortage.

While some spinning mills are working in two shifts, while others are running in single shift only. There are 120 spinning mills in the state which produce 687,884 metric tonnes of cotton yarn per annum.

They export Rs 842 crore worth cotton yarn to various countries and states. Spinning mills are directly providing employment to one lakh workers and indirectly generating employment to four lakh workers.

Almost all the spinning mills have reduced 40 per cent of cotton yarn production for the last three months. According to sources in the AP Textile Mills Association, due to the lockdown, textile mills in West Bengal, Gujarat, Tamil Nadu and Maharashtra States are not purchasing cotton yarn.

Every spinning mill on an average has been producing 25 metric tonnes to 30 metric tonnes of cotton during the last three months. Over Rs 350 crore to Rs 450 crore worth cotton yarn stocks are piled piled up in the spinning mills. As a result the mills are facing working capital problem and unable to pay loan installment to banks, maintenance expenses.

When the COVID-19 cases were on rise, the workers working in the spinning mills went to their natives places taking their last year experience into consideration.

As a result the spinning mills are working with the available workers. If the same situation continues, the spinning mills will face severe financial crisis, adds Reddy

Japan’s clothing retailer Uniqlo Co has clarified that the shirts, whose imports have been blocked by the United States, are made from cotton sourced from outside China. As per Japan Times, the shirts are made at a plant in China using cotton procured from outside the country. Uniqlo emphasized that there has been no confirmation of forced labor during the manufacturing process for the items.

In January, U.S. Customs and Border Protection blocked imports of Uniqlo brand shirts for possible violation of a US ban related to suspected forced labor in China's Xinjiang Uyghur autonomous region.

Uniqlo said its imports of other products manufactured at the same Chinese plant have bee permitted. The shirts are not subject to seizure by US authorities although their import was not allowed. The brand clarified that it has no direct transactions with Xinjiang Production and Construction Corps, a major producer of Uyghur cotton under the wing of the Communist Party of China.

The cotton used in the shirts in question was sourced from multiple countries other than China and the company has submitted certificates of origin to the CBP.

Sustainability technology platform Higg aims to unlock a comprehensive view of a business’ social and environmental impacts in value chain operations. As per Eco Textile, since 2019, Higg has helped manufacturers improve their environmental scores by nearly 20 per cent in the two years since it formed.

The platform enables companies to measure, manage and share the social and environmental impacts of their value chain, It has become the industry's 'go to' for sustainability measurement since it span out from the Sustainable Apparel Coalition (SAC) in 2019. Higg has broadened its reach from around 20,000 users to more than 45,000, including tens of thousands of manufacturers in 120 countries; while more than 500 fashion brands have committed to using its brand and retail tool.

It has developed a suite of tools which together make up a comprehensive platform for sustainability insights for responsible consumer goods businesses, beginning with the fashion industry.

Higg has also been building its leadership team with former executives from Nike and Microsoft, and growing from 20 employees in 2019 to 73 today.

In its sustainability report for 2020, Danish fashion giant Bestseller claims to have achieved important sustainability goals despite the pandemic. As per an Eco Textile report, the company sourced 84 per cent of its cotton more sustainably in 2020 with organic cotton accounting for nearly a quarter of its total consumption.

Bestseller also increased the use of more sustainable man-made cellulosic fibres from 11 to 34 per cent, and increased the amount of recycled polyester used to 10 per cent of the total. The 2020 sustainability report also highlights Bestseller's success in achieving greenhouse gas reduction goals in line with the Paris Agreement and a 1.5°C pathway through the Science Based Targets initiative (SBTi).

The retailer also launched the Fashion FWD Lab, an experimental platform, which acts as catalyst for collaboration with innovators and entrepreneurs to pilot and test new ideas and solutions. Its brands Vero Moda, Object and Selected became some of the first to produce garments at market scale from Renewcell’s Circulose fibre which is made from discarded textiles, such as production waste and worn-out garments.

Alongwith Cyclo and GMS Composite Knitting, Bestseller also developed a closed-loop system which recycles cutting scraps to make cotton yarn and fabric. Around 219 or its suppliers completed a Higg FEM assessment, representing 86 per cent of the company's supply chain by value.

Owner of brands like The North Face, Vans and Timberland, VF Corporation is creating a new 'Child Rights Action Pledge' to strengthen the protection of children’s rights and eliminate child labour throughout the global apparel supply chain by 2025.

As per Eco Textile, VF’s new pledge embodies all important work done by them till date and its aspirations to be a leading industry advocate for children’s rights. As a part of its pledge, the company plans to integrate the Children’s Rights and Business Principles developed by UNICEF, the United Nations Global Compact and Save the Children.

In addition, VF Corp aims to strengthen its child rights efforts through increased due diligence in upstream supply chain; a formal policy for the prevention, mitigation and remediation of child labor; a review of supply chain purchasing practices, including wages and working conditions for parents and caregivers and enhanced NGO partnerships focused on supporting children, advancing education and addressing the root causes of child labour

The United Nations has declared 2021 the International Year for the Elimination of Child Labor. According to the International Labour Organization (ILO), even after a 38 per cent decline in the last decade, 152 million children across the world are still engaged in child labor.