FW

Indian clothing industry exports have grown on an average by 10 per cent a year in the course of the last decade. In addition to accounting for 4.5 per cent of international textile trade, India is becoming one of the largest consumer goods markets in the world. Valued at $58 billion a year, the Indian domestic textile and apparel market is expected to reach $141 billion by 2021.

The objective is to reach $24.9 billion in clothing exports by 2020, compared to $16 billion last year. This vast potential has led to the establishment of a first textile university project, which will come up in Gujarat. The growth of Indian clothing exports will be sustained by the expansion expected in world clothing trade and partly due to the rupee’s depreciation.

Readymade garments were the largest contributor to total textile and apparel exports from India in financial year ’15. The segment had a share of 40 per cent in overall textile exports. Cotton and man-made textiles were also major contributors with shares of 31 per cent and 16 per cent respectively.

However, the withdrawal of focus market scheme for cotton yarns has caused a steep decline in exports to non-conventional markets like Peru, Morocco etc.

Germany and Turkey plan to collaborate in textiles sector. The focus will be on technology fields of nonwovens, clothing, decoration, coating and environment. Another business area will be testing services. The aim is to strengthen mutual partnership through joint development projects, exchange of know-how and promotion of commercial and academic training.

The German textile machinery sector is Turkey’s main technology partner. The long tradition of German-Turkish cooperation will be strengthened and further expanded. A common research and development centre will be set up in Istanbul, Turkey. In the facility in Istanbul, partners and industrial customers in Turkey will be acquired, supported and involved in joint development projects. In addition, German and Turkish companies will be assisted in the development of markets in each other’s country. The transnational co-operation will be supported in particular through intensive partnerships with industrial associations, universities and research institutes in Turkey and further expanded.

With a focus on higher quality, the creation of brands as well as development of technical textiles, the Turkish textile industry is getting ready for future challenges. The Turkish textile industry is interested in using German technology to cope with the tough competition from Asia.

Brussels recently hosted the Tripartite Social Summit, which focussed on jobs, growth and convergence in Europe. While Jean-Claude Juncker, President of the European Commission participated in it and Klaus Huneke, Euratex Vice-President Treasurer, spoke on behalf of the textile and clothing industry.

In his speech Huneke said one of the largest consumer goods sectors in the world is the textile and clothing (TC) sector and the EU TC industry is a leader in world. More than 30 per cent of the exports to the world comprise of EU while the EU Single Market is also one of the most important in terms of size, quality, and design. Over 170,000 companies, with more SMEs are a part of the industry and they provide employment opportunities to 1.6 million workers, majorly women.

The industry is diversified—from fibres to clothing and technical textiles, within which there are further sub-sectors and they have some common interests and diverging in some other cases on industrial needs. National and European Social Partners have played an important role with regard to this over the years.

Huneke pointed out EU Social dialogue is a fundamental tool to support sustainable development of the TC industry. EU Social Partners welcomed the announcement about strengthening of social dialogue and greater involvement of the social partners. He feels that the European Commission should reaffirm and respect the role of independence of social partners in consultation procedures on social legislation and also ensure that they are fully involved topics specifically relevant to their industry. Appropriate processes need to be in place to ensure the requirement of sectorial social partners’ input in the entire process of the European Semester.

Indorama Ventures, one of the world’s leading petrochemical producers and a leading global manufacturer of PET resins, fibers, filaments and wool yarns plans to add 15,000 tons of extrusion-based fiber spinning capacity to Auriga Polymers. Its products serve major players in diversified end use markets, including food, beverages, personal and home care, health care, automotive, textile and industrial. The company acquired a manufacturing site Auriga Polymers in South Carolina, US, in 2011. ndorama.

For several years, Auriga Polymers has been broadening its polyester staple fiber offering to fast-growing nonwoven fabric industry. With this new expansion, Auriga will be able to produce fibers based on environmentally-friendly polymers such as PLA as well as specialty polyester and post-consumer recycled polymers.

Thailand-based Indorama Ventures portfolio comprises the Necessities and High Value-Added categories of polymers, fibers and packaging. The company is positioned among the lowest cost polyester chain producers in the world. It is the largest PET producer in the world.

Indorama Ventures’ business consists of three key verticals - feedstock, PET and fibers and yarns. In a proactive move towards maximising its value chain and operational synergies, Indorama Ventures has expanded its PET and polyester businesses in recent years.

www.indorama.net/

Small and medium sized hosiery manufacturers in India have raised concerns over the introduction of an anti-dumping duty against imported polyester yarns from China or Thailand. Although the duty has been imposed to provide relief to local producers from an influx of cheap raw materials, small-scale hosiery manufacturers have expressed fears that businesses could be adversely affected.

One effect of the loss of cheap yarn is that hosiery manufacturers will be forced to bear the brunt of the increased costs of raw materials rather than passing on the higher costs to consumers. Thousands of manufacturers who were earlier procuring yarn in bulk from China and Thailand will now be forced to buy it in Indian market on higher rates, the effect of which subsequently be transferred to the consumers.

These manufacturers feel prices of hosiery products will see a rise but at the same time the move by the government will discourage unhealthy competition. The move apparently seems to be guided by the ruling government’s make in India plan where it encourages the purchase and selling of finished goods and raw material prepared indigenously.

The anti-dumping duty will be effective for a period of five years beginning October 21, 2015.

The German trade fair organised by Messe Frankfurt dedicated to textiles and home textiles, Heimtextil will be held on January 12 to 15, 2016.

In 2015, there were 2,723 exhibitors, and in 2016, the number is expected to rise. Decorative fabrics and furnishings, including textiles for furniture and decoration and digital printing, the latter in international growth for its applicability also to home textile, will be displayed at the roof. Also, there will be a conference titled, 'European Digital Textile Conference by WTiN'.

The focus will be on area trends, which will stress the importance of well-being. Thus, there’s a theme park too. Helen Sac WGSN said that wellness is the new luxury and the focus for a growing number of companies is well-being, which is why they chose it as the theme of the Park.

Olaf Schmidt, Vice-President Textiles & Textile Technologies, during a presentation to the press about the fair, presented data from an industry in Germany, which after a dip of two years (2012-2013) is growing again. In 2014, in fact, the textile market turnover reached 10.1 billion Euros (+ 20 percent on 2013) and continues to grow in the first half of 2015 with a 2.4 percent to 5.2 billion. Exports in 2014 (+ 3.9 percent) compared to imports, were up 4.3 percent, and by June this year, exports grew by 3.2 percent and imports recorded a + 6.3 percent. Schmidt said that the trend of returning to growth made them optimistic for the coming months.

www.messefrankfurt.com

The 3-day high-level conference targeting the full spectrum of textile-manufacturing innovative technology applications and market trends, Textile World Innovation Forum 2015 will be held from December 1-3, 2015 at Sheraton Charlotte Airport Hotel, Charlotte, NC. Industry professionals for whom time is a constraint can get a high-value dose of the latest developments across the full textile spectrum—process technologies, trends and quick insights into hot topics in the textile market through this single-track, high-level event.

This conference was designed with professionals’ unique business needs in mind. Thus, management personnel in engineering, processing, plant operations, research and development, and quality control can avail of every insight in the textile world at this event.

Professionals from these fields will get unique insights into diverse areas of textile manufacturing such as, fibre, spinning, knitting, weaving, nonwovens, dyeing, printing, finishing, apparel manufacturing, and special-interest areas that may be adapted to their own operations. All this will be offered by the Forum at the conference.

In recognition of their outstanding efforts and accomplishments in product invention and innovation, a dinner will be hosted by the Innovation Forum for the Textile World Innovation Award for 2015, for one company.

Besides, the Quantum Group, Colfax, NC, along with its four sister companies, has been selected to receive the 2015 Innovation Award Recipient award. This is because of the company's long-standing commitment to innovation in the textile industry and incredible ability to solve clients’ challenges.

Textile units’ owners in Rajasthan and the government are at odds over the cost of setting up a common effluent treatment plant. The plant is estimated to cost around Rs 120 crores but mills say they don't have this much money and have urged the government to set up the plant. The court has asked the state and the Centre to share 50 per cent of the cost while the textile units’ owners would bear the remaining 50 per cent cost. Effluent treatment plants are designed to treat effluents coming from different processes of the plant. The treatment of different effluents varies with the type of effluent. Water effluent treatment systems are designed to treat effluents.

The issue of a common effluent treatment plant has been pending since 2003 when the high court had instructed owners to set up the plant. Later, the Supreme Court had also asked them to follow orders. In 2014, after receiving the environmental clearance from the Rajasthan State Pollution Control Board, the owners gave their consent to set up the plant.

As per a study conducted in 2012, a total of 650 units were functional in the Sanganer region, discharging 12.3 MLD of effluents. However, officials maintain that the actual figure is much higher. They say that more than 17 MLD effluents are being discharged.

A team comprising commercial enterprises, government representatives and the Nepal Pashmina Industry Association promoted high-quality, cashmere garments and fashion accessories under the Chyangra Pashmina trademark at the 6th Edition of Cashmere World. This is the only specialist commercial event for cashmere and fine fibres in the international exhibition calendar

Naindra Prasad Upadhaya, Secretary Ministry, Government of Nepal (GON, Ministry of Commerce and Suppliers, Nepal made a presentation on ‘Can the environmental footprint and the procurement process be lightened?’ at the corresponding event, Cashmere World Forum.

Upadhaya informed delegates about key areas addressed by the industry, and news of advances in cashmere fibre and finished cashmere merchandise production, of Nepal’s initiative in the cashmere business and presented statistics. The country’s commitment to the cashmere sector, exports of finished goods being responsible for approximately $26 million in 2014, was confirmed through his presentation, ‘Advancing supply and socio-economic development through quality enhancement of Chyangra Pashimina – High Mountain Cashmere from Nepal’.

He said that project was their first step to ‘green’ the industry to preserve our beautiful natural landscape in Nepal. In total 11 booths were occupied by Nepalese at the exhibition, of which three enterprises promoted the Pashmina trademark. The companies, Harati Woollens Knitwear, Shree Pashmina Industry, and Samanta Pashmina Crafts displayed a wide range of cashmere products, which included sweaters, scarves, women’s and children’s wear.

However, as Shuaihua Wallace Cheng, MD for China at International Centre for Trade and Sustainable Development and a Yale World Fellow for 2015, points out there is a need for the US government to look at inking a deal that help the overall development of its partner countries.

TPP’s strengths and implementation of SDGs

With more than 18,000 tariff lines reduced to zero, according to a fact sheet provided by the Office of US Trade Representative, 12 countries will merge into a more integrated market. This will significantly lower transaction costs for firms to trade among the TPP members, boosting economic growth and creating jobs.

The TPP pact, Cheng states, has one chapter dedicated to labour rights to prevent the race to bottom. Its members make an explicit statement supporting international core labour standards, from the freedom to form unions and bargain collectively to prohibitions against child labour and forced labour, and protection against employment discrimination. Although these standards are only minimum requirements to all signatory countries under the International Labour Organisation, this is the first time they will be incorporated in a large regional trade agreement with ‘teeth’, namely, possible trade sanctions against producers who violate core standards, Cheng points out.

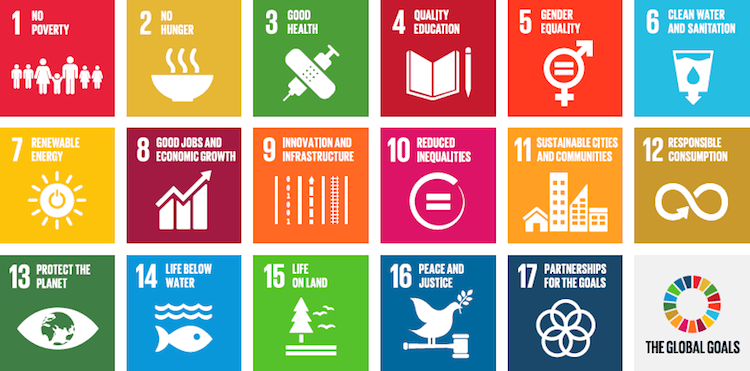

Cheng argues this agreement will make some positive contributions to other sustainable development goals, by emphasizing good governance, anti-corruption measures and codes of conduct with high standards. TPP also has a chapter on development and capacity building. These are in line with the SDG 16 addressing justice and good governance and SDG 17 on effective partnership.

TPP’s negative impact on poor countries

However, Cheng says that the TPP agreement will negatively impact poor countries and people in vulnerable situations, while the SDGs obligate all countries to carry out an effective partnership to “work in a spirit of global solidarity, in particular solidarity with the poorest and with people in vulnerable situations.”

Citizens of a poor country outside the negotiations, he points out, will have no say at all on how TPP will affect their interests. For example, US subsidies to cotton farmers have been the largest concern for cotton farmers in poor countries. According to a research by Oxfam, US cotton farmers receive three times more in subsidies than the entire USAID budget for Africa’s 500 million people. Trade-distorting cotton subsidies have pushed down the global price of cotton, costing Benin, Burkina Faso, Chad and Mali more than US $100 million a year.

Even for Vietnam, the poorest developing country within the TPP, export potentials in labour-intensive sectors such as textile and clothing will be compromised by a restrictive “yarn forward” rule of origin insisted on by the US – if Vietnamese clothing exporters would like to enjoy the TPP market’s zero tariff, all components, from yarn to fabric to final item, must be produced by one of the members to the agreement. Note that the US is the most competitive producer of yarn, thread and fabric among the TPP countries.

Cheng says the US cherry-picked practices in the Doha Development Round negotiations of the World Trade Organization. The US negotiators have preliminarily secured the trade facilitation agreement, the expansion of information technology agreement and possible liberalization of environmental goods under the WTO frameworks, for which their business groups lobbied. However, the US leaves behind critical issues for developing countries, such as trade-distorting domestic farm subsidies, anti-dumping rules and tariff escalation of some products, he says.

In conclusion Cheng says in a new context of pursuing the Sustainable Development Goals over the next 15 years, the world needs leadership. As a nation promoting universal values of freedom, democracy and equality, the United States is in a good position to lead, he says, adding, the US political leaders should not merely follow US business interests, but stand for these higher values.

In this TPP agreement, the US has made positive steps in promoting trade for growth, strengthening environmental and labour protections in international commerce, and advancing anti-corruption principles, however, the country fails to support sustainable development by refusing to discontinue subsidies harmful to poorest countries outside the TPP, by insisting on the yarn-forward rule of origin and pushing unbalanced intellectual property protections that will likely cost lives, he avers.

If President Barack Obama would like to be remembered as a great global leader rather than a follower of business interests, he may need a bigger legacy than TPP, Cheng asserts, adding, there is a chance at the upcoming December WTO Ministerial Meeting in Nairobi, where the President should ask his trade officials to work more constructively with trading partners and deliver a more development-friendly package than the TPP.

www.un.org