FW

Bangladesh wants better prices for its garment products from foreign buyers. Reason: Production costs have shot up due to factory upgradation and also workers’ wages have increased. BGMEA say the proceeds will be spent on furthering welfare of readymade garment workers.

Wages have hiked wages by over 200 per cent since 2009. Besides, dormitories are being set up for women working in garment units. An additional port has come up alongside the existing ports in Chittagong and Mongla. As per BGMEA president Md Atiqul, before launching the inspection program to improve safety standards in the RMG sector, the global buyers promised to raise prices of apparel products, but did not do so, rather they took the opportunity to lower the prices

European and US companies that focus on apparel market’s value segment plan to expand the share of their sourcing from Bangladesh to 25 to 30 per cent by 2020 from an average of 20 per cent now. Midmarket brands, which generate about 13 per cent of their sourcing value in Bangladesh, plan to increase that share to 20 to 25 per cent over the same period. While growth in current product categories will drive some of the increase, 63 per cent of the chief purchasing officers want to expand into more fashionable or sophisticated items such as formal wear and outerwear.

Attractive prices are the most important reason for purchasing in Bangladesh. Price levels there are expected to remain highly competitive in the future since significant efficiency increases may offset rising wage costs.

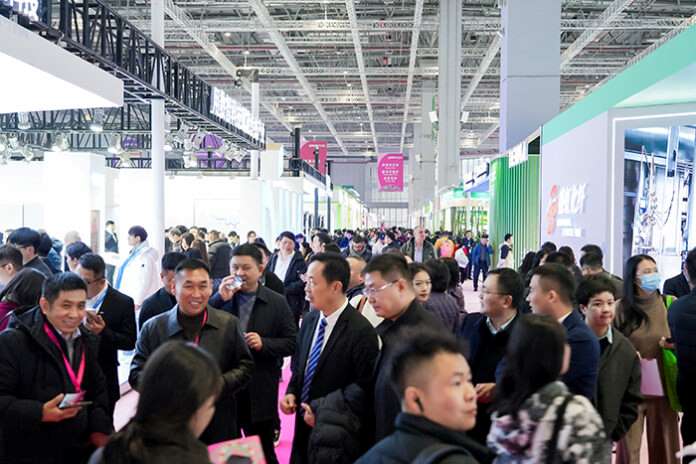

Chinese business platform, CHIC Autumn, will take place for the first time in October. Around 600 exhibitors are expected to attend the event slated from October 13 to 15. Later in March, CHIC will take place at the modern National Exhibition and Convention Center in Shanghai.

CHIC opens the way to Chinese consumer market for smaller high-end brands with less volume. Matchmaking, networking and further activities to connect international brands with the Chinese retail market underline the position of CHIC as mediator in the fashion business. This edition of CHIC will cover 75,000 sq. mtr. area, comparatively small to the March event. The autumn edition reflects the fashion rhythm and gets ready as a platform to focus the merchandise and not the enormous image booths like in March exhibition. It refers to the order season of international brands presenting their Spring/Summer collections.

The October fair will focus on Spring/Summer collections across all categories: womenswear, menswear, kidswear, shoes/bags/accessories and swim/bodywear. Parallel to CHIC Intertextile will take place at the same fairground and the concept of ‘Show in Show’ will continue. London PURE organizer will, after their first start in October 2014, be integrated in CHIC as PUREshanghai. Around 50 exhibitors will be presenting in this area.

Also Preview in China, the South Korean trade show, will be participating as longtime exhibiting group at CHIC in October. Brazilian show association ABICALCADOS will also have a pavilion at the event.

www.chic-online.com.cn

When it comes to textile machinery, the one country that supplies the most to the world is Italy. Italy’s market share of world textile machinery exports is around 11 per cent. It has about 300 companies producing textile machines and related accessories. The value of Italian production was €2.3 billion in 2014, with exports worth €1.9 billion. Since there’s a wide supply base, Italian machinery manufacturers are able to cater to a wide variety of customers worldwide. Of the total sales, exports comprise 84 per cent and it goes to 130 countries.

What has helped the industry grow in Italy is globalization coupled with innovation. This has allowed Italian companies to consolidate and cement their position globally.

Stroking export growth

The first quarter results of 2015 reveal, Italian textile machinery exports was highest to Asia at 42per cent, followed by Europe 41 per cent, Latin America 7 per cent, North America 5 per cent and Africa 5 per cent. China was the largest market for Italian textile machinery in Q1, which imported machinery worth €58 million. Turkey was next with exports from Italy worth €47 million, followed by Bangladesh €31 million and India €25 million.

All classic textile sectors are supplied with Italian machines. The textiles machinery sectors in Q1 was divided into: 22 per cent spinning machines, 8 per cent weaving machines, 14 per cent knitting machines, 29 per cent dyeing, finishing and printing machines, 24 per cent accessories and 3 per cent other machines.

Return of ITMA to Italy

After 20 years, textile machinery expo ITMA has made come back to Italy. Indeed, the domestic industry is keen to strengthen its position in the global market place and wants to use this event as a stepping stone to bigger things. As Raffaella Carabelli, President of ACIMIT (Association of Italian Textile Machinery Manufacturers), stated at a press conference held on the 70th anniversary of ACIMIT, Italian machinery manufacturers will occupy 30 per cent of the total exhibition space at ITMA. They will cover about 31,000 sq. m. of exhibition space.

Carabelli further added that not only do statistics place Italy in the number one position across the world, they also testify on the vitality of the country’s textile industry. Meanwhile machinery manufacturers are focusing on innovations and the range to be displayed at the fair. The support extended by the Ministry of Economic Development and the Italian Trade Agency is vital in this as a whole range of activities have been implemented, aimed at promoting Italy’s textile machinery industry and its participation at ITMA. Several initiatives have been planned, one of them is inviting foreign delegations during the course of this year. Nearly 200 textile operators from more than a dozen countries are expected at the next ITMA show in Italy.

The Trans-Pacific Partnership (TPP) trade agreement, of which Vietnam is a member, is expected to reach its conclusion later this year. And with its signing, the Southeast Asian country is emerging as the hot destination for Indian investments. The TPP is a proposed regional free trade agreement aimed at eliminating tariffs and lowering non-tariff barriers that is being negotiated by 12 countries throughout the Asia-Pacific region, which collectively contribute almost half of global output and over 40 per cent of world trade. The 12 countries include Australia, Brunei, Canada, Chile, Japan, Malaysia, Mexico, New Zealand, Peru, Singapore, the United States and Vietnam.

India is eyeing an opportunity to invest in creating a manufacturing base in Vietnam for export to the other TPP member countries to enjoy the free trade access. The Indian government last week launched a preferential credit package worth $300 million for investments in the garment and textile sector of Vietnam over 10 years, according to the Vietnam Textile and Apparel Association (VITAS). India would be supporting investment projects in the garment and textile sector using Indian-made equipment and service up to 75 per cent of the total funding estimated for a single project. The entire credit package, with an interest rate of two per cent per annum for a 10-year term, is conducted through Vietnamese Eximbank under the guarantee of the Ministry of Finance, the VITAS said.

The package will help Indian businesses develop new factories in Vietnam, as well as promote cooperation between Vietnamese and Indian partners in the same field. This is also an opportunity for businesses to gain more advantages after Vietnam joins the TPP trade pact, the VITAS said, citing a document from the Indian government.

Italy is set to announce a €20 million initiative that will help strengthen its relationship with America in the field of textiles, fashion and leather goods exports. Carlo Calenda, Italy’s vise minister of economic development, is to soon detail the Ministry of Economic Development’s year-long plans to help boost exports in these categories. The plan involves trade shows, special events, incoming services and assistance in Italy and a major media campaign.

Maurizio Forte, Trade Commissioner and Executive Director for the US of the Italian Trade Commission believes the American market has the biggest potential and will grow consistently in coming years just the way it has until now. And though Italian labels are present in the coasts, in New York and Miami on the East Coast and Los Angeles on the West, they weren’t present in other places. Therefore, there is great scope for growth in central US states, such as, Texas, Colorado, Montana, etc.

The initiative will benefit Italian brands tremendously, which are present since the eighties. The quality of country’s produce is good, thus it saw a rise in 2014 contributing to a 4.5 per cent market share since 2013.

Export of cotton fabrics, both woven and knitted to Bangladesh and Sri Lanka has been welcomed by Cotton Textiles Exports Promotion Council (Texprocil). This is under the Merchandise Exports from India Scheme (MEIS). A fresh list of textile products that are eligible for exports sops was announced recently by the Director General of Foreign Trade (DGFT). The MEIS scheme, introduced in the Foreign Trade Policy 2015-20 announced recently allows duty credit scrips at the prescribed rates of 2 per cent, 3 per cent and 5 per cent. This is on exports of items to certain countries classified under Group A, B and C.

Texprocil chairman R K Dalmia sees this as a very positive step as it will increase exports to the two countries. Knitted fabrics with H S (Harmonised System) Code 6006, which covers most of the knitted fabrics, though, are excluded from the benefits. Knitted fabrics with Lycra are value added products, which are being widely used in garments. Texprocil wanted the entire range of fabrics to be covered under the benefit to avoid unintended exclusions.

Also, exports of value-added and labour-intensive products such as cotton dyed and printed fabrics and made-ups to different African countries like Mauritania, Mali, Dar Es Salaam, etc, are not included by the MEIS.

Silk Mark Vanya is being held in Kochi from July 22 to 27. Weavers, silk cloth merchants, co-operatives and government departments from the traditional silk producing states of Karnataka, Tamil Nadu, Andhra Pradesh, West Bengal, Jammu and Kashmir, Uttar Pradesh, Chhattisgarh, Jharkhand, Assam, Tripura, Madhya Pradesh and Kerala are exhibiting their collection at the expo. The main aim of the show is to teach people to recognize 100 per cent pure silk from the fake.

The expo features a diverse collection of silks like Kanchipvaram, aarani, crepe, kantha, georgette and many more. Exhibited are a number of silk products like silk carpets, bedspreads, cushions, wallets and also shirts, churidars and scarves. Viewers will be able to see the different stages of silkworms, silk extraction and weaving live. Silk Mark Vanya is an initiative of the Central Silk Board, Union Ministry of Textiles. It is conducted by the Silk Mark Organization of India. With almost 2,700 Silk Mark authorised silk merchants in Kerala, this is the seventh time SMOI is conducting an exhibition.

Silk Mark was launched in 2004. Silk Mark labels are in the form of paper hang tags and sew-in labels. These are affixed only on pure silk products. Each label has a hologram and an unique number printed on it which helps the consumers to trace the product to its authorised user.

silkmarkindia.com/

As per a report by ENDS Europe hormone disrupting chemicals have been found in imported clothing, which are an ‘unacceptable risk’ to the environment. So, to tackle this, EU members states have all agreed to ban this toxic substance that is found widely in clothing. Everyone unanimously voted in favour of extending existing restrictions on nonylphenol ethoxylates (NPE) to imports of clothing and other textile products. This would also protect the sea life. Use of the chemical in textiles was banned in Europe 10 years ago. The substance though is still released in the seas through imported textiles being washed. This chemical is used in textile manufacture as a cleaning, dyeing and rinsing agent. NPE accumulates in the bodies of fish and disrupts their hormones, harming fertility, growth and sexual development.

Sweden had put forth the proposal in 2013. It was backed by scientists at the European Chemicals Agency (ECHA). A study by Greenpeace in 2011 found NPE in two-thirds of clothes tested. This included items sold by big brands such as H&M, Lacoste and Adidas, as well. Though the concentrations of NPE found in the clothing was low, the chemical’s ubiquity in the environment was a risk.

Five years after the European Commission adopts the ban on textiles, it will come in force. This is expected to happen next month.

With many established brands sourcing from the country, Sri Lanka is aiming to be the leader in swimwear market. The country is well on the way to becoming the swimwear destination of the world. At one time, Sri Lanka was known for T-shirts, jeans and intimate apparel. Now the island is planning a swimsuit fashion show on August 7 and 8. The aim is to be the number one swim show in the world and showcase its designers and supply chain partners and Sri Lanka’s destination as one of the most beautiful beach spots in the world.

Swimwear is strategic to Sri Lanka in terms of both fashion consumption and manufacturing. The aim is to compete with top swimwear shows in Miami, and Sao Paulo. The island is armed with technologies like bonding, flocking and laser cutting. With a well-developed supply chain, Sri Lanka is poised to meet orders faster, unlike in the beginning, when materials had to be brought from China or Vietnam.

This ability cuts down lead time by almost half. Swimwear is seasonal and it is not possible to plan much ahead. It’s necessary to design and plan closer to the season.

Pakistan wants to increase its textile exports in the next five years. Special incentives would be given to small and medium enterprises. New schemes and initiatives will be launched to increase the use of information technology. The plan envisages making textile sector compliant with labor and environment rules and conventions domestically and internationally. Textile units will be encouraged to use modern management practices for improving efficiency and reducing waste. The government will also provide vocational training to 12,000 workers.

Pakistan is the eighth largest exporter of textile products in Asia and the fourth largest producer of cotton with the third largest spinning capacity in Asia after China and India. Organisational rules will be amended to extend incentives to employees on the basis of performance and output. The proposed measures include formulation of a new policy as well as restructuring of institutions dealing with cotton to promote availability of better cotton for the value-added sector in the textile value chain.

Cotton standardisation and clean cotton with reduced contamination levels will be facilitated through upgradation of ginning machinery. A comprehensive training and capacity building program would be developed to establish a system in the private sector for grading and classifying cotton, ensuring that proper premiums are paid on cotton.