FW

In a significant trade development, the United States has imposed a 25% tariff on all Indian imports, effective from Aug 01, 2025. This move deals a strong blow to India’s export sectors, particularly textiles, garments, and home furnishings. Announced by President Donald Trump on July 30, the tariff comes in response to India’s “high tariffs, non-monetary trade barriers, and continued energy trade with Russia.”

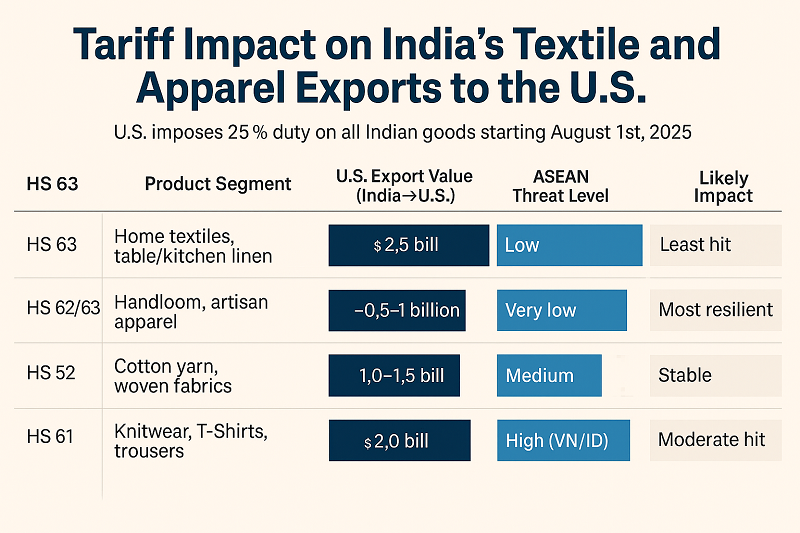

While the tariff raises concerns across India’s export-dependent sectors, a closer look at product categories reveals a mixed picture. Some segments appear more insulated due to limited competition, while others are exposed to cheaper alternatives from ASEAN nations.

US Imports From India: $10 bn textile pipeline at stake

In 2024, India exported nearly $10 billion worth of textiles and apparel to the US, accounting for approximately 28–29% of its global Textile & Apparel (T&A) exports. Globally, the U.S. imported $107 billion worth of textiles, making India its third-largest supplier.

However, India’s product-wise advantage isn't uniform. According to UN COMTRADE and Moneycontrol, India holds over 50% market share in key U.S. imports such as:

|

Product Category |

Imports from India ($ Mn) |

India’s Share of U.S. Imports (%) |

|

Cotton bed linen |

817.5 |

59.40% |

|

Textile fabrics printed/laminated with plastics |

273.6 |

56.60% |

|

Carpets knotted |

176.4 |

59.70% |

|

Carpets tufted |

141.8 |

72.40% |

|

Table linen, of cotton |

129 |

72.90% |

|

Toilet and kitchen linen |

78.1 |

50.50% |

|

Basketwork, wickerwork (partially textile) |

140 |

56.00% |

In total, more than $3 billion worth of U.S. textile imports have over 60% dependence on Indian suppliers, making them less vulnerable to sourcing shifts, even with the new tariffs.

Who’s Hurt Most? : HS Code impact breakdown

HS 61 – Knitwear & Cotton Apparel-Includes: T-shirts (6109), knitted trousers (6103)

● India’s U.S. Export: ~$2 billion

● Competitive Landscape:

○ Vietnam (20%) and Indonesia (19%) are now 5% cheaper than India post-tariff.

○ Bangladesh (35%), Cambodia (36%), and China (30%+) remain more expensive.

HS 63 – Home Textiles & Crafted Linen-Includes: Bed linens (6302), towels, table linens

● India’s U.S. Export: ~$2.5 billion

● Advantage: India’s design-led, artisan-rich goods face minimal ASEAN competition.

According to Moneycontrol, India supplied:

● 83% of U.S. carpets & rugs

● 73% of table linen

● Over 60% of 13 key textile lines

This makes HS 63 India’s most resilient export category despite the tariff hit.

HS 52 – Cotton Yarn & Fabrics

● India’s U.S. Export: $1–1.5 billion

This is a less competitive segment where India enjoys a significant scale advantage; ASEAN nations do not dominate here.

HS 62/63 – Handloom & Ethnic Fashion-Includes: Sarees, GI-tagged scarves, embroidered apparel

● India’s Share: ~$0.5–1 billion

These are unique products without mass-production competition from ASEAN.

Tariffs May Bite Short-Term, But India’s Position Remains Strong:Experts say

Rahul Mehta, Chief Mentor, CMAI, explains, “This will make our products 7% to 10% more expensive than some of our competitors, and it will certainly hurt our apparel exports to the US... but it’s not beyond our ability to face.”

Sanjay K Jain, Chairman, ICC National Textiles Committee, observes, “Vietnam & Indonesia have a 5% advantage—but China, Bangladesh, Myanmar, Cambodia are at a disadvantage. USA buyers want to reduce dependency on China & Bangladesh—so where will they go?” He adds, “India does not have capacity for more than 10% growth right now—but buyers already committed to India will continue. Yes, it's a 5% hit, but it's manageable.”

He warns, however, of a bigger concern: “The penalty threat linked to Russia is the real worry. India must act—remove the 11% import duty on U.S. cotton and use savings from oil to subsidize export duties on U.S.-bound goods.”

Competitor Tariffs: Who benefits?

|

Country |

Tariff to U.S. (Post-2025) |

|

Vietnam |

~20% |

|

Indonesia |

~19% |

|

Bangladesh |

~35% |

|

Cambodia |

~36% |

|

China |

~30% + extra duties |

|

India |

25% (new) |

Despite India’s setback, the tariff differential still positions it at par with or ahead of several major exporters, especially in home and ethnic textiles.

Near-term disruption, long-term opportunity?

According to Mehta, “Fortunately, this set-back has come at a time when we’ve just signed an FTA with the UK and are proceeding rapidly with the EU. So yes, it’s tough times—but not panic time.” Sanjay Jain echoes, “Maybe the bullish feel is gone—but certainly not bearish. Apparel growth will continue—India is in a neutral position globally.”

Strategic Takeaway: Where India stands strongest

|

HS Code |

Segment |

U.S. Value |

ASEAN Threat |

Tariff Advantage |

Outlook |

|

HS 63 |

Home textiles, table/kitchen linen |

$2.5 B |

Low |

High |

Least Hit |

|

HS 62/63 |

Handloom, artisanal fashion |

~$1 B |

Low |

High |

Most Resilient |

|

HS 52 |

Cotton yarn & woven fabrics |

$1–1.5 B |

Medium |

Moderate |

Stable |

|

HS 61 |

Knitwear, T-shirts, trousers |

~$2 B |

High (VN/ID) |

Low |

Moderate Hit |

Tactical response needed, not panic

The 25% tariff poses a challenge, but India’s dominance in key U.S. categories like home textiles, carpets, and ethnic linens acts as a natural buffer. The real exposure lies in cotton apparel, where Vietnam and Indonesia now gain an edge.The path forward may lie in policy action—as Jain suggests—removing cotton duties and incentivizing value-added exports using savings from Russian oil.

As global sourcing shifts and FTAs with the UK and EU move forward, India’s textile sector remains challenged but not cornered. Its resilience may yet convert this crisis into a competitive advantage.

The global fashion industry is on the threshold to cross the $1 trillion mark by 2027. Yet beneath the glitter of runways and the allure of digital lookbooks, a more pragmatic revolution is taking hold—one driven not by moodboards or muse-inspired silhouettes, but by numbers. Fashion in 2025 is not abandoning creativity; it’s weaponizing it with data. And at the heart of this shift lies a single truth: Key Performance Indicators (KPIs) are no longer optional—they are existential.

The rise of KPI-led fashion

For decades, fashion operated largely on instinct, trend cycles, and creative gut-feel. But in a world where fast fashion is competing with responsible sourcing, and personalization must scale globally, decision-making needs sharper tools. That tool is measurement.

In today’s hypercompetitive environment, where consumer expectations shift faster than hemlines, KPIs have become the new compass. They align artistic vision with operational discipline and serve as a common language from design studios in Milan to factory floors in Tiruppur. Gone are the days when “best guess” planning sufficed. As a stakeholder put it, “You can’t manage what you don’t measure—and in fashion, what you don’t manage bleeds money and trust.”

Why KPIs are the industry’s new lifeline

Bridging vision with execution: KPIs bring structure to a chaotic value chain. When designers, merchandisers, marketers, and supply chain teams align around the same measurable goals—like sell-through rates or time-to-market—decision-making becomes collaborative rather than siloed.

Reducing waste, increasing accountability: Fashion’s sustainability crisis is no secret. With overproduction and markdowns choking profit margins and landfills, metrics like return reasons and deadstock percentages help brands cut excess before it starts. Efficiency isn't just profitable—it's ethical.

Replicating success through insights: Creative success in fashion is often perceived as lightning in a bottle. But KPIs offer repeatability. By analyzing what designs outperform, why certain SKUs return more, or which campaigns convert better, brands can continuously refine and replicate their wins.

Driving financial discipline: Margins are thinning, and competition is unforgiving. By tracking the percentage of full-price sales or understanding how iterations impact development costs, companies can take control of profitability. KPIs make value creation measurable.

What to Measure: The KPI framework for 2025 and beyond

Fashion's complexity demands KPIs that span every facet of the business. Here's a breakdown of the essential metrics defining the smartest global brands.

Table: Product Performance: Tracking what sells, what stumbles

|

KPI |

Definition |

Impact |

|

Sell-through Rate |

Percentage of units sold versus units produced for each style |

Identifies popular styles and informs future production planning. |

|

Return Rate/SKU |

Percentage of returns for each product, tracked by specific reason (e.g., fit, quality, damage) |

Highlights product deficiencies and improves customer satisfaction. |

|

Time-to-Market (Days) |

Duration from initial sketch to product launch |

Streamlines the product development cycle and enables faster trend response. |

|

# of Bestsellers/Collection |

Styles that consistently exceed sales targets or sell out completely |

Identifies high-performing designs and informs future collection strategies. |

|

Per cent of Collection Sold at Full Price |

Percentage of items sold without markdowns |

Measures the effectiveness of pricing strategies and product desirability. |

Table: Development Efficiency: Accelerating creation without compromise

|

KPI |

Definition |

Impact |

|

Number of Iterations/Style |

Number of design revisions required before final sample approval |

Optimizes the design process and reduces development costs. |

|

Sample Approval Rate |

Percentage of samples approved on the first round |

Indicates the accuracy of initial designs and technical specifications. |

|

Per cent of Tech Packs Completed on Time |

Percentage of technical specifications delivered by their deadlines |

Ensures smooth production handoffs and adherence to launch schedules. |

|

# of Styles Completed vs. Planned |

Actual number of styles finalized compared to the initial seasonal plan |

Assesses planning accuracy and resource allocation efficiency. |

Table: Supply Chain & Production: Creating a transparent, timely backbone

|

KPI |

Definition |

Impact |

|

% of Materials with Verified Certifications |

Percentage of raw materials meeting specific sustainability or ethical standards |

Ensures compliance with industry standards and aligns with brand values. |

|

On-Time Delivery Rate from Suppliers |

Percentage of orders received from suppliers by the agreed-upon date |

Prevents production bottlenecks and ensures timely product launches. |

|

% of Suppliers with Full Traceability Data |

Percentage of suppliers providing complete supply chain information |

Essential for transparency and compliance with evolving regulations like the Digital Product Passport (DPP). |

Table: Sustainability KPIs: Beyond profit, towards purpose

|

KPI |

Definition |

Impact |

|

Average CO₂ Footprint/Product |

Carbon emissions associated with each product's entire lifecycle |

Reduces environmental impact and appeals to growing eco-conscious consumer base. |

|

% of Products with Repair/Reuse/End-of-Life Plans |

Percentage of products designed for circularity or responsible disposal |

Promotes circular economy principles and enhances brand reputation. |

|

Waste-to-Approved Sample Ratio |

Amount of waste generated per approved sample |

Minimizes material waste during the design and development process. |

|

Use of Deadstock or Recycled Materials (%) |

Percentage of materials sourced from existing inventory or recycled content |

Reduces reliance on virgin resources and promotes sustainable sourcing. |

Table: Innovation & Validation: Future-proofing product development

|

KPI |

Definition |

Impact |

|

% of New Styles Validated with Waitlists/Pre-orders |

Percentage of new designs generating early customer interest before mass production |

Reduces the risk of unpopular launches and gauges market demand effectively. |

|

# of User-Tested Prototypes/Season |

Number of prototypes tested with target consumers |

Ensures product-market fit and enhances user experience. |

|

% of Products with Customer Feedback Data Attached |

Percentage of styles with integrated customer reviews and feedback |

Informs future design decisions and improves customer satisfaction. |

|

% of Styles Integrated with a DPP |

Percentage of products linked to a Digital Product Passport for transparency |

Meets regulatory requirements and enhances brand transparency and trust. |

Table: Team & Strategy: Cultivating a data-driven culture

|

KPI |

Definition |

Impact |

|

# of Cross-Department Design Reviews Held |

Number of collaborative design review meetings between teams |

Fosters inter-departmental collaboration and strategic alignment. |

|

% of Collection Aligned with Brand DNA or Themes |

Percentage of styles reflecting core brand identity and seasonal narratives |

Maintains brand consistency and strengthens brand recognition. |

|

# of Styles Aligned with Business Goals (Margin, Timing, Audience) |

Number of styles meeting specific financial, timeline, and target audience objectives |

Ensures the product portfolio contributes directly to overall business success. |

From art to algorithm, its a new fashion era

In 2025, fashion brands no longer have the luxury of ignoring data. The stakes are too high, and the competition too agile. Those that fail to adopt a KPI-led mindset will struggle not just with profitability, but with relevance.

In a world where Gen Z demands authenticity, regulators demand transparency, and consumers demand speed, KPIs offer a single path forward: clarity. Because fashion’s future won’t be shaped by trends alone—but by those who know why the trend worked, how to replicate it, and what it contributed to the bottom line.

The newly launched 2024 Impact Report by the global leader in outdoor, active, and lifestyle products, Columbia Sportswear Company details the company's advancements across its three core corporate responsibility pillars: Empowering People, Sustaining Places, and Responsible Practices.

The comprehensive report showcases work accomplished by Columbia Sportswear's four primary brands: Columbia, SOREL, Mountain Hardwear, and prAna. A few of these notable achievements from 2024 include exceeding 80 per cent of their ‘Planet Water’ goal, which aims to provide 100,000 people daily with access to clean water; employees contributing over 6,100 volunteer hours to various causes; Mountain Hardwear receiving the Corporate Partner of the Year award from Leave No Trace; a significant reduction in absolute energy consumption at their Oregon distribution center and headquarters, with declines of over 900,000 kilowatt-hours and nearly 67,000 therms between 2022 and 2024 and the RISE industry initiative reaching over 425 workplaces and impacting more than 375,000 workers, over 65 per cent of whom are women.

In addition to these, Columbia Sportswear also completed a Sustainability Accounting Standards Board (SASB) disclosure for 2024, outlining its Environmental, Social, and Governance (ESG) efforts in accordance with industry-specific standards.

Founded in Portland, Oregon, in 1938, Columbia Sportswear Company connects active individuals with their passions through innovative apparel, footwear, accessories, and equipment. Its diverse portfolio of brands is sold in over 100 countries worldwide.

To be organized by the Development Commissioner for Handlooms, Ministry of Textiles and curated by the Material Library of India, the second edition of ‘Weave the Future 2.0: Celebrating Handlooms, Regeneration & Indigenous Cotton's Bright Future’ will open on National Handloom Day, August 7, 2025, and run until August 17, 2025, at the Crafts Museum in New Delhi.

The event will highlight the crucial role of handlooms in building a sustainable and circular textile economy in India. The exhibition champions traditional, nature-aligned practices, emphasizing how handlooms can enable mindful, culturally rooted, and circular production systems. It seeks to celebrate a new generation of textile artisans who are reimagining fashion through regenerative and handmade practices.

A significant focus is placed on promoting indigenous cotton varieties such as Kala Cotton, Punasa Cotton, Konda Patti Cotton, Gavran Kapus Cotton, and Jayadhar Cotton. These varieties are highlighted for being hardier, drought-resistant crops that support ecological balance and rural livelihoods. The event aims to raise awareness and build momentum to increase the current 2-3 per cent share of indigenous cotton in India's total cotton cultivation.

The event promotes ‘regeneration’ in textiles, encompassing not just recycling but also practices that restore and revitalize the environment and communities. It brings together approximately 30 participating brands and initiatives including a diverse group of weavers, artisans, designers, enablers (like Laudes Foundation and Regenerative Production Landscape Collaborative (RPL) in Madhya Pradesh), and grassroots implementers (such as KORA Collective and Khamir) who are actively involved in reviving regenerative textile practices.

The event will feature installations that expand the conversation around sustainability, craft, and storytelling. Examples include a soundscape installation by Sonam Khetan, an exploration of native cotton varieties by Kora Design Collaborative, and an eco-printed panel by Lafaani.

The National Council of Textile Organizations (NCTO) has applauded President Donald Trump for his executive order to eliminate the ‘de minimis’ exemption for all global commerce shipments, effective August 29.

Kim Glas, President and CEO, NCTO, issued a statement praising the decision, which addresses a long-standing concern for the American textile industry. For eight years, NCTO has campaigned against the de minimis loophole, which allows approximately 4 million packages daily to enter the U.S. duty-free and without rigorous inspection. Half of these shipments are estimated to be textiles and apparel.

The de minimis mechanism has functioned as a black box for low-cost, subsidized, and unethical Chinese imports, Glas states, highlighting how it undermines the competitiveness of US manufacturers. This loophole has facilitated the entry of goods made with forced labor from Xinjiang, China, and even illicit fentanyl, reaching American consumers unchecked, she emphasizes.

A key member of the Coalition to Close the De Minimis Loophole, NCTO thanked President Trump for recognizing the ‘severe impact’ of this provision. The executive order restores fairness for US manufacturers, closes a major gateway for illegal and toxic goods, and lays the groundwork for reinvestment and job creation here at home, Glas adds.

The organization notes, coupled with bipartisan legislation to codify the de minimis repeal by July 2027, this executive order effectively slams the door shut on one of the most damaging trade loopholes in US history. The US textile supply chain currently employs 471,046 individuals, generated $63.9 billion in shipments in 2024, and exported $28.0 billion in fiber, textiles, and apparel last year.

The global Home Textile Market is projected to grow by 4.2 per cent CAGR from 2025-33 to approximately $213.5 billion by 2033.

The market's steady expansion is primarily fueled by several key factors. These include consumers’ increasing expenditure on home décor with the rise of urbanization and a greater emphasis on interior aesthetics. These are fuelling demand for products like bed linen, curtains, towels, and upholstery fabrics, driven by evolving lifestyle trends and increasing disposable incomes, particularly in emerging economies. The booming real estate and hospitality sectors are also contributing significantly to market growth.

Furthermore, eco-friendly and sustainable textiles are gaining considerable traction, reflecting a growing consumer awareness of environmental concerns. The accessibility and sales of home textile products have also been significantly boosted by the rise of e-commerce platforms.

Looking ahead, ongoing technological advancements in fabric manufacturing and digital printing are expected to continue shaping and influencing the market landscape.

Renowned Italian luxury group, Ermenegildo Zegna NV and Venezio Investments. an indirect wholly-owned subsidiary of Singapore-based investment company Temasek Holdings have entered into a significant investment agreement.

According to this agreement, Temasek has agreed to purchase 14,121,062 of Zegna's treasury shares at $8.95 per share. This price aligns with the volume-weighted average of ZGN share prices from June 30 to July 25, 2025.

With this new transaction, combined with its previous acquisition of 12,699,981 ordinary shares through market purchases, Temasek's total stake will reach 10 per cent of Ermenegildo Zegna Group's ordinary share capital outstanding after the deal closes.

Ermenegildo ‘Gildo’ Zegna, Chairman and CEO, states, their investment is a strong endorsement of the company’s vision and long-term growth potential, while firmly recognizing the global significance of the Italian luxury sector. Temasek’s partnership helps the company strengthen their organic expansion globally and to reinforce their unique role as a custodian of truly authentic brands.

Nagi Hamiyeh, Head-EMEA, Temasek, highlights the investment as a commitment to supporting leading European businesses with global potential. Having successfully established itself in the high-end luxury segment, the Ermenegildo Zegna Group presents significant long-term value creation opportunities across each brand, states Hamiyeh, adding, Temasek looks forward to being a ‘thoughtful, long-term partner’ to the Zegna family and management team.

Upon the transaction's closing, the Ermenegildo Zegna Group will receive a total cash consideration of $126.4 million. This injection will help boost the Group's balance sheet, providing enhanced financial flexibility to seize opportunities for accelerating the organic growth of its brand portfolio. Temasek's extensive experience in the luxury sector and deep knowledge of the Asian market are expected to significantly contribute to Zegna's growth prospects and support expansion in key underdeveloped geographies.

Italian luxury fashion house Prada SpA announced a robust 9 per cent Y-o-Y increase in its consolidated net revenues, reaching €2.74 billion (~$3.15 billion) for during H1, FY25 ended June 30, 2025. This growth was attributed to high brand desirability and creative momentum across all regions, despite a turbulent macroeconomic environment. Retail sales notably climbed 10% year-on-year to €2.45 billion (~$2.81 billion), fueled by sustained momentum in both established and emerging markets.

The Group's Adjusted EBIT stood at €619 million, representing a healthy margin of 22.6 per cent, consistent with the previous year despite increased investments in brand development. Net income for the period reached €386 million, and Prada concluded the semester with a solid net cash position of €352 million, even after a €398 million dividend payout and €294 million in capital expenditure.

Miu Miu emerged as the Group's standout performer, with retail sales rising by an impressive 49 per cent Y-o-Y in H1, FY25 and 40 per cent in Q2, FY25. The brand's strong appeal spanned across product categories and geographies, boosted by initiatives like Miu Miu Upcycled, Miu Miu Custom Studio, and new immersive store experiences, including a three-story boutique in SKP Wuhan and a redesigned New Bond Street flagship.

In contrast, the Prada brand faced challenging comparative figures and a subdued global demand, recording a resilient but slight retail sales decline of 1.9 per cent in H1 and 3.6 per cent in Q2. Despite this, Prada continued to build cultural relevance through dynamic storytelling campaigns and expanded its physical presence with key launches like Prada Men on 5th Avenue and the Mi Shang Prada Rong Zhai hospitality venue in China.

Acknowleding the challenging backdrop, Patrizio Bertelli, Chairman and Executive highlighted the results as beign a testament to the brands’ strength and disciplined execution. Andrea Guerra, Group CEO attributed the performance to the cultural relevance of our brands, their creativity and ability to anticipate and interpret contemporaneity.

Geographically, Asia Pacific posted a 10 per cent increase in retail sales, maintaining strong momentum. Sales in Europe also grew by 9 per cent, while the Americas showed continued recovery with a 12 per cent increase. Japan saw a 4 per cent rise, and the Middle East significantly outperformed with a 26 per cent jump in retail sales.

In strategic moves, the Group announced in April its acquisition of Versace from Capri Holdings for €1.25 billion, expected to close in H2 subject to approvals. Prada Group also completed a 10 per cent equity investment in Rino Mastrotto Group, a global leather and luxury manufacturing services supplier. Sustainability efforts continued across raw materials, chemical management, and traceability.

French luxury brand Hermès registered a 5 per cent decline in net profit during H1, FY25 to €2.2 billion ($2.53 billion). However, the brand’s sales grew by 7.1 per cent to €8 billion ($9.2 billion) during the period. Excluding the one-time contribution, net income for the group's share actually increased by 6 per cent to €2.5 billion ($2.88 billion).

Axel Dumas, Managing Director hailed the ‘solid first-half results in all regions,’ emphasizing the company's commitment to continue to invest and recruit to ensure the continued success of the company.

The company’s sales in the Americas rose by a robust 9.5 per cent to €1.45 billion ($1.67 billion), propelled by double-digit growth in the United States despite a more volatile market. Dumas addressed concerns regarding the newly announced 15 per cent customs duties on exports to the US, stating he was waiting for the precise rules of the game. He clarified, the 15 per cent rate might include the earlier 10 per cent implemented in April and the existing 5 per cent, which would mean no further price increases from Hermès, which had already raised US prices by 5 per cent after the April tariff hike.

Dumas also highlighted another significant factor: ‘the falling dollar,’ noting its impact could be as substantial, if not more, than the tariffs.

Regionally, the company’s sales in Asia excluding Japan increased by 1.5 per cent increase to €3.57 billion ($4.11 billion), with Dumas observing, the sales atmosphere in China remains buoyant for the company. Japan experienced a 17.6 per cent growth in sales to €815 million ($937 million). In Europe, sales excluding France grew by 12 per cent to surpass the billion-euro mark (€1 billion / $1.15 billion), while sales in France itself increased by 8.7 per cent to €740 million ($851 million).

Looking at product categories, sales in Hermès' core business, leather goods and saddler increased by 11.3 per cent to €3.58 billion ($4.12 billion). Sales of clothing and accessories rose by 4.3 per cent to €2.25 billion ($2.59 billion). However, perfumes and beauty products experienced a 4.1 per cent decline to €248 million ($285 million), and watch sales fell by 8.9 per cent to €281 million ($323 million).

The United States' announcement today of a sweeping 25% tariff on a wide range of Indian goods, effective August 1, 2025, has sent shockwaves through India's export-oriented sectors. While the new duties cover diverse industries from automobiles to electronics, the textile and garment sector, a cornerstone of India's manufacturing and employment, faces a particularly challenging new reality. This aggressive move by the Trump administration, citing "obnoxious" non-tariff barriers and India's continued ties with Russia, fundamentally alters the competitive landscape for Indian exporters in the crucial US market.

Sanjay K. Jain, Chairman of the ICC National Textiles Committee, offered his perspective on the development: "The recently announced tariff by the USA of 25% plus penalty for buying from Russia. That plus is yet to be defined. But overall, it's not good news for India. 25% is still manageable as Bangladesh has 35%, China has 30% plus. But Indonesia and Vietnam, two of our competitors are at 20% plus the EU is lower than that. However, the more worrisome thing is the plus. We don't have it defined. How much is it going to be? I hope this plus is not defined and we stay at 25% where we'll still be almost in equilibrium with our overall, if you see on the average with our competitors for textiles, mainly home textiles and apparels."

Historically, the US has been a vital destination for Indian textiles and apparel, with exports surpassing $2.5 billion in 2025. India's share in the global apparel market, while having seen recent growth, stood at 2.94% in 2024, down from 4.05% in 2017, largely due to intensifying competition from other Asian players. The imposition of a 25% tariff on top of existing duties will now significantly erode India's price competitiveness, forcing exporters to re-evaluate strategies, absorb costs, or desperately seek new markets.

India's Tariff Nightmare: An instant disadvantage

Prior to today's announcement, import duties on Indian goods in the US were generally much lower, often below 3% for many product categories. With the addition of a 25% tariff, Indian textile and garment products will now face a significant hurdle, making them considerably more expensive for American buyers.

This situation puts India at a distinct and immediate disadvantage compared to its major competitors in Asia, who face varying tariff regimes with the US.

The Battlefield: Asian rivals and their US tariff edge

Here's a breakdown of the current tariff situations for India's key competitors in the US textile and garment market, as of today, July 30, 2025:

● Brazil: 50%.

● Myanmar: 40%.

● Thailand: 36%.

● Cambodia: 36%.

● Bangladesh: 35%.

● Canada: 35%.

● South Africa: (Tariff not specified in provided data).

● Sri Lanka: 30%.

● Libya: 30%.

● Iraq: 30%.

● Mexico: 30%.

● South Korea: 25%.

● Malaysia: 25%.

● Kazakhstan: 25%.

● Tunisia: 25%.

● Brunei: 25%.

● Philippines: 20%.

● Vietnam: 20%.

● Indonesia: 19%.

● EU: 15%.

● Japan: 15%.

Hard Numbers: Export Values and Their New Tariff Shackles

|

Country |

2024/2025 US Textile & Garment Exports |

Effective US Tariff (Approximate) |

|

China |

Substantial (declining) |

30+% (Minimum) |

|

Vietnam |

Growing (H1 2025: $18.67B) |

20% |

|

India |

$2.5B |

25% + Penalty |

|

Bangladesh |

$7.34B |

35% |

|

Indonesia |

Significant (declining for some) |

19% |

Note: Export figures are approximate and represent recent annual or half-yearly data where available. Tariff rates are as of today, July 30, 2025, and are subject to change based on specific product categories and ongoing trade negotiations.

Fallout and Future: India's uphill battle

The 25% tariff is a crippling blow to India's textile and garment industry. Exporters will face immense pressure to either absorb the increased cost, which will severely impact their already thin margins, or pass it on to US buyers, making their products virtually uncompetitive. This could lead to:

● Aggressive market diversification: Indian exporters will likely intensify efforts to explore and aggressively expand into non-US markets, particularly Europe, where they might find more favorable trade terms.

● Urgent product re-engineering and value addition: To counter the tariff burden, Indian manufacturers may be forced to focus on higher-value products or niche segments where quality and design can command a premium, making the tariff less impactful on overall pricing.

● Desperate government intervention and negotiations: The Indian government will be under immense pressure to engage in urgent, high-stakes diplomatic efforts with the US to seek a rollback or significant reduction of these tariffs. This could involve addressing US concerns regarding trade barriers and geopolitical stances.

● Accelerated supply chain exodus from India: US buyers, already diversifying away from China, now have another complex layer to their sourcing strategies. They may further accelerate shifts towards countries like Vietnam or other ASEAN nations that offer relatively lower tariff burdens, even if it means significant adjustments to their existing supply chains with India.

Sanjay K. Jain expressed a cautious optimism, stating, "I don't see India's exports going down. Still due to China being the largest and still having Bangladesh, both of these countries still have higher tariffs. I think so we still are positive, but the positive has been diminished to a very small extent from what we all were expecting." He added, "We were expecting India to also get a 20% tariff rate, just like Vietnam and Indonesia, which would have put them at par and been good relative to other countries. So I don't see this as a negative. It's just a disappointment from what positivity we were seeing."

The textile and garment industry, a major employer in India, particularly for MSMEs, stands at a critical juncture. The newly imposed 25% tariff, coupled with the varied and often more favorable tariff situations of its competitors, necessitates a rapid and strategic response from both the industry and the Indian government to navigate this challenging new global trade landscape. The coming months will reveal the true extent of the shift in US sourcing patterns and India's ability to adapt to this significant trade barrier.