The textile industry has taken an immense leap in the digital printing sector. One of the utmost promising developments in the textile industry is digital fabric printing. It has unlocked the doors for numerous prospects to enhance the quality and sustain the growing demands of textile printing. Worldwide market value for digital textile printing expanded to CAGR (Compound annual growth rate) of $1.88 billion in 2018.

Specialists have forecast that global digital textile printing production will be around 1.6 billion square meters annually by 2019. Digital systems are set to continue this fascinating prospect as the products of the fashion, signage and home-made industries add new business models and value to the industry. This will upsurge the total value of the market by $3.75 billion in 2023 and will grow to consume over 2.70 billion m².

Specialists have forecast that global digital textile printing production will be around 1.6 billion square meters annually by 2019. Digital systems are set to continue this fascinating prospect as the products of the fashion, signage and home-made industries add new business models and value to the industry. This will upsurge the total value of the market by $3.75 billion in 2023 and will grow to consume over 2.70 billion m².

Dye-sublimation printing, in particular, has seen dramatic growth in the past several years, and direct-to-fabric printing is poised to displace some of the “traditional” transfer-based dye-sublimation printing. Improved print head design and higher-quality substrates are also strong drivers of growth of digital textile printing. Complement on top of that the phenomenal growth of “soft signage,” and it is hard to find a pessimistic forecast.

Digital Textile Printers are seeking more precise ways to determine the type of equipment and determine the length of time for printing. It has been revealed that print service providers are focusing on their printing technology for digital textile printing automatically. Worldwide, 22.2% of the Digital Textile Printing Market of the Polyester segmented to register the CAGR. The most frequently used digital textile printing are Direct to Fabric (DTF) and Direct to Garment (DTG) segment by printing process accounting more than 80% of the market portion of digital textile printing market.

Electronics for Imaging, Inc. is a leading international company based in Silicon Valley that specializes in digital printing technology, believes that digitally printed textiles will grow at 10-15% in the next several years.

“Mimaki” is another foremost manufacturer equipped with a wide range of solutions for textile printing. Yuji Ikeda, General Manager of global marketing at Mimaki Engineering, recently said to Textile Today that the market is growing and believes it will continue to do so at an extraordinary pace.

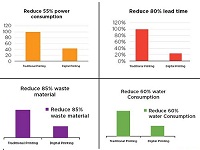

Eco-friendly mechanisms, high design flexibility, low-cost ornaments are the main motives for the growth of digital printing technology. The traditional textile printing process takes approximately 6-8 weeks to take 3-10 days through digital printing technology.

technology. The traditional textile printing process takes approximately 6-8 weeks to take 3-10 days through digital printing technology.

Difference between traditional digital printing

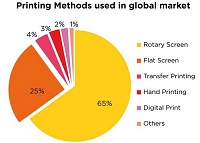

China produces nearly one-third of all printed textile in the world. Likewise, currently, the market segment of digital textile printing is only one to two percent. Compare to that 65% of the rotary screen printing is made, 25% by flat screen printing and made by handprint. Contrary to expectations, digital printing has scarcely any impact on the traditional printing process.

Printing Methods global market

Bangladesh’s 86% of exports emanate from textile and textile products. In the field of digital printing, Bangladesh factories are doing significantly well. According to the data of BTMA (Bangladesh Textile Mills Association), Bangladesh has 240 dyeing-printing-finishing mills.

Bangladesh’s 86% of exports emanate from textile and textile products. In the field of digital printing, Bangladesh factories are doing significantly well. According to the data of BTMA (Bangladesh Textile Mills Association), Bangladesh has 240 dyeing-printing-finishing mills.