FW

The Indian cotton spinning industry is entering a high-stakes transition in H2 FY26 as the ‘trickle-down’ effect of punitive US tariffs begins to bite. Effective August 27, 2025, a cumulative 50 per cent duty on Indian apparel - driven by reciprocal trade policies and geopolitical friction over Russian oil - has forced Indian exporters to offer aggressive discounts. This burden is now vibrating through the entire value chain, with ICRA projecting a 4 per cent–6 per cent revenue decline for spinners in FY26. While H1 FY26 remained flattish, the second half is bracing for a 50–100 basis point margin contraction as yarn realisations moderate under global pressure.

Market adaptation and MMF competition

Exporters are currently losing an estimated Rs 45 crore daily, leading to a strategic pivot toward the EU market ahead of a potential free trade agreement. Domestically, while the exemption of cotton import duties and relaxed Quality Control Orders (QCO) for Man-Made Fibers (MMF) offer some cost relief, they present a double-edged sword. Competitive pricing on imported VSF and polyester fibers is expected to squeeze domestic MMF yarn manufacturers, exposing them to intensified global competition. Trade finds its own course, noted government officials, yet for spinners, the course currently involves stabilizing contribution levels at Rs 98–100/kg to survive the H2 squeeze.

A Moody’s Ratings affiliate, ICRA is a premier Indian credit rating agency providing deep-dive analytics for over 60 sectors. Its textile sample set covers 30 per cent of industry revenue, monitoring 1,600+ benchmarks including cotton-to-yarn spreads. Faced with US-bound order cancellations of up to 70 per cent in some categories, ICRA forecasts stagnant capacity expansion for 2026.

In a major strategic recalibration, the Chinese government has approved a sweeping tariff adjustment plan set to take effect on January 1, 2026, targeting the backbone of its textile and apparel industry. By slashing provisional duties on 935 imported products, Beijing is positioning its domestic spinning and weaving mills to absorb global inflationary shocks. The most aggressive cuts focus on cotton, where most-favored-nation (MFN) tariffs for uncarded and uncombed varieties will plummet from 6 per cent to 1 per cent. This move is expected to significantly lower the production overhead for China's massive spinning hubs, further widening the cost-competitiveness gap between Chinese yarn and regional rivals like Bangladesh and Vietnam.

Fueling the high-value fiber cycle

The 2026 plan extends beyond basic cotton, offering a lifeline to the luxury and technical textile segments. Tariffs on scoured and greaseless wool will decline to 1 per cent, while combed wool duties are being hacked from 8 per cent to 3 per cent. By reducing the entry cost of high-grade natural fibers, China is moving away from volume-led manufacturing to high-value yarn production, noted a senior analyst at the Ministry of Finance. In the leather sector, duties on wet blue bovine hides will be halved to 3 per cent, exclusively targeting industrial inputs to bolster the domestic footwear supply chain. While finished apparel remains protected by standard rates, these ‘upstream’ cuts ensure China remains the world’s most efficient ‘processing sink,’ even as

Western brands experiment with near-shoring.

Under the State Council, the Customs Tariff Commission manages China’s import-export duty framework. In 2026, it will maintain zero-tariff treatment for 43 least-developed countries and honor 24 free trade agreements including RCEP. Its 2026 outlook focuses on ‘new productive forces,’ lowering costs for advanced materials and green technology inputs.

A massive $950 million real estate transaction involving 119 JCPenney locations has officially collapsed, but the retailer is using the setback to signal operational stability. The deal with private equity firm Onyx Partners hit a wall ahead of the December 2025 deadline, following a legal dispute over incomplete deliverables. However, Catalyst Brands - the powerhouse entity formed in January 2025 through the merger of JCPenney and Sparc Group - has clarified that the failed transfer from Copper Property CTL Trust will not impact store service. Instead of closing, these locations will remain the bedrock of a $9 billion retail portfolio that now includes Aéropostale, Brooks Brothers, and Eddie Bauer.

Scaling the ‘Catalyst’ ecosystem

The termination of the real estate deal coincides with a broader ‘Make It Count’ turnaround strategy, where JCPenney is reinvesting $1 billion into digital and store-level upgrades. By integrating its 646 locations with Sparc's high-growth specialty brands, Catalyst Brands is targeting a unified loyalty program for 60 million customers. While the Trust must still liquidate properties by January 30, 2026, to satisfy creditors from the 2020 bankruptcy, JCPenney’s triple-net master leases ensure these stores continue to anchor American malls. This pivot marks a transition from a liquidation mindset to a growth-oriented ‘zombie mall store king’ strategy, leveraging AI-Copper Property CTL Trustdriven supply chains to $1 billionmaintain a competitive edge.

Catalyst Brands is a 2025 joint venture merging JCPenney with Sparc Group, owned by Simon Property Group, Brookfield, Authentic Brands, and Shein. Serving 60 million shoppers across 1,800 global locations, the group manages iconic labels like Liz Claiborne, Brooks Brothers, and Nautica. With over $9 billion in revenue, Catalyst focuses on omnichannel innovation and operational scale.

Lululemon is closing 2025 with a strategic offensive, leveraging its new ‘Train’ collection -fronted by seven-time F1 champion Lewis Hamilton - to reignite a brand that has seen its stock slide over 40 per cent this year. While domestic US sales faced a 3 per cent contraction in Q3, the Canadian pioneer is banking on ‘Science of Feel’ technical innovations and an aggressive international playbook to fill the gap. High-margin items like the Wunder Train No Line and the License to Train shorts are being positioned as versatile ‘brunch-to-burpee’ apparel, a critical move as the brand transitions toward its ‘Power of Three ×2’ goal: doubling its men’s business and quadrupling international revenues by 2026.

Global expansion and leadership shifts

As the company nears its $11 billion revenue target for fiscal 2025, it has announced a record-breaking entry into six new markets for 2026, including India (via Tata CLiQ) and a major European cluster (Greece, Austria, Poland). This expansion serves as a hedge against a maturing North American market and looming tariff headwinds. With Calvin McDonald, CEO set to step down in January 2026, the brand is in a pivotal transition. Analysts note that while US consumer engagement has softened, a 46 per cent growth in Mainland China sales suggests the premium athleisure moat remains intact. The focus now shifts to a 35 per cent ‘newness penetration’ target for Spring 2026 to recapture full-price sell-through.

Founded in 1998, Lululemon is a premium technical apparel leader targeting a $12.5 billion revenue milestone by 2026. Operating nearly 800 stores globally, it dominates the yoga, run, and training categories. Following its 2025 international surge, the brand is now scaling into footwear and high-end menswear.

A massive $950 million real estate transaction involving 119 JCPenney locations has officially collapsed, but the retailer is using the setback to signal operational stability. The deal with private equity firm Onyx Partners hit a wall ahead of the December 2025 deadline, following a legal dispute over incomplete deliverables. However, Catalyst Brands - the powerhouse entity formed in January 2025 through the merger of JCPenney and Sparc Group - has clarified that the failed transfer from Copper Property CTL Trust will not impact store service. Instead of closing, these locations will remain the bedrock of a $9 billion retail portfolio that now includes Aéropostale, Brooks Brothers, and Eddie Bauer.

Scaling the ‘Catalyst’ ecosystem

The termination of the real estate deal coincides with a broader ‘Make It Count’ turnaround strategy, where JCPenney is reinvesting $1 billion into digital and store-level upgrades. By integrating its 646 locations with Sparc's high-growth specialty brands, Catalyst Brands is targeting a unified loyalty program for 60 million customers. While the Trust must still liquidate properties by January 30, 2026, to satisfy creditors from the 2020 bankruptcy, JCPenney’s triple-net master leases ensure these stores continue to anchor American malls. This pivot marks a transition from a liquidation mindset to a growth-oriented ‘zombie mall store king’ strategy, leveraging AI-Copper Property CTL Trustdriven supply chains to $1 billionmaintain a competitive edge.

Catalyst Brands is a 2025 joint venture merging JCPenney with Sparc Group, owned by Simon Property Group, Brookfield, Authentic Brands, and Shein. Serving 60 million shoppers across 1,800 global locations, the group manages iconic labels like Liz Claiborne, Brooks Brothers, and Nautica. With over $9 billion in revenue, Catalyst focuses on omnichannel innovation and operational scale.

The next feature, we present as part of our year-end series, 'Wrap Up 2025, Outlook 2026', as the global textile and apparel (T&A) industry closes the books on 2025,a year defined by aggressive tariff adjustments and a race for supply chain transparency—the sector is crossing a decisive commercial threshold. If 2025 was the period of emergency transparency measures, 2026 is emerging as the year of operational and strategic autonomy. The industry has moved beyond an era where technology was a peripheral efficiency tool to one where it functions as the central floor manager, strategic business advisor, and lead procurement officer capable of navigating the most volatile geopolitical headwinds.

The 2026 market outlook confirms that Smart Factory 2.0 is no longer a pilot concept but a mandatory operational standard. In the production hubs of Tiruppur, India, and Ho Chi Minh City, Vietnam, factories have integrated high-velocity Computer Vision systems that scan fabric at speeds of 60 meters per minute. Catching microscopic fiber defects and seam misalignments with 90% precision, these units have driven a 15% reduction in fabric waste. This provides a critical financial buffer in a market where raw material costs continue to squeeze margins.

Strategic Command: The AI CEO as the defensive shield

In 2026, technology has moved "upstream" from the factory floor into the boardroom, evolving into a Global Chief Strategist that navigates complex risks. With the U.S. implementing steep unilateral tariffs—which reached a staggering 50% on certain Indian textile segments by late 2025—and the EU activating its Carbon Border Adjustment Mechanism (CBAM) on January 1, 2026, successful enterprises now use AI to run "Scenario Stress Tests." By simulating various tariff outcomes and shipping disruptions, these systems reallocate production across geographical lines in real-time to protect the bottom line.

For instance, when geopolitical tensions triggered supply shocks in 2025, smart platforms functioned as Business Model Advisors, immediately suggesting a shift toward the UK, Oman, and Australia to leverage newly ratified Free Trade Agreements (FTAs). This "Dynamic Sourcing" capability, powered by AI that tracks port congestion, raw material price indices (like the Global Cotton Index), and currency fluctuations—has reduced the impact of supply chain shocks by an estimated 12% across the sector.

|

Strategic Challenge |

AI "Chief Strategist" Intervention |

Measured Outcome (2025-26) |

|

Tariff Volatility |

Scenario Simulation & FTA Optimization |

8% Margin Protection via Regional Re-allocation |

|

Raw Material Spikes |

ML-Driven Commodity Price Forecasting |

10% Reduction in Procurement Costs |

|

Supply Chain Gaps |

Real-Time Logistical Digital Twins |

18% Improvement in Delivery Reliability |

|

Sustainability (DPP) |

Blockchain & IoT Provenance Tracking |

100% Compliance with EU CBAM Reporting |

The 2026 CEO Profile: Transitioning from creative oversight to data governance

The leadership requirements for global fashion houses have undergone a total overhaul. The traditional CEO profile has been replaced by the "Orchestrator CEO," who relies on AI for Business Model Innovation. Leadership performance is now measured by Model Accuracy and the strength of "AI Ethical Guardrails." A brand’s most liquid asset is its "Digital Twin", a verified data shadow of every garment that authenticates its origin, environmental footprint, and resale potential, acting as a permanent record of the brand's strategic integrity.

Operational Resilience: The "Just-Tight-Enough" production model

The industry is formalizing a shift away from "Just-in-Time" logistics toward a "Just-Tight-Enough" manifesto, advised by algorithms that value capital preservation over volume. The historical practice of over-ordering by 20% to mitigate supply chain volatility is now viewed as a critical drain on working capital. Instead, the sector is adopting "Micro-Batching." By utilizing predictive analytics to delay bulk production until consumer demand signals are verified, brands are scaling winning lines in 21-day cycles.

This "Platformization" of manufacturing has enabled a "Manufacturing-as-a-Service" (MaaS) model. Platforms like StyTrix (by Makalot) leverage decades of historical production data to reduce physical sampling waste by 70%. This allows brands to remain asset-light, launching collections without the burden of inventory risk.

Regional Trade Trajectories: 2026 strategic map

Manufacturers are specializing geographically to align with new trade corridors and regulatory zones, guided by AI that identifies the most "digitally compatible" partners.

|

Region |

Commercial Identity |

2026 Growth Driver |

Strategic Leverage |

|

India |

The Resilience Leader |

Man-Made Fibers (MMF) |

18 FTAs (UK, Australia) & PM MITRA Smart Parks. |

|

Vietnam |

The High-Tech Hub |

AI-Driven Production |

Transitioning to "Smart Factory 2.0" for luxury cycles. |

|

Turkey / EU |

The Speed Hub |

Circularity Infrastructure |

72-hour delivery to EU; advanced recycling tech. |

|

USA / Mexico |

The USMCA Fortress |

Vertical Integration |

Regional protection; 21-day lead times for US retail. |

Agentic Commerce: The shift to Machine-to-Machine transactions

The most significant change in the transactional space is the rise of Agentic Commerce. B2B procurement is moving toward Machine-to-Machine (M2M) interactions. At major retailers like Walmart or Zara, human procurement teams are being supported by AI Agents that communicate directly with factory ERP systems.

In this environment, "relationship-based" sourcing has been replaced by Data Integrity. If a supplier's digital interface cannot "talk" to a retailer's autonomous agent, which now triggers replenishment based on real-time sell-through, that supplier is effectively removed from the bidding pool. This has birthed a new legal reality: the first "Data Integrity" lawsuits were filed in late 2025 against suppliers who provided inaccurate carbon data to procurement agents, marking the start of a high-accountability era where AI acts as a Risk Mitigator.

Editor’s Conclusion: The disappearance of the ‘Middle Ground’

As we analyze the 2026 horizon, it is evident that the "middle ground" in the textile business has vanished. The market has bifurcated into two lanes: Ultra-Fast/Ultra-Low-Cost (volume-driven) and Ultra-Transparent/High-Value (margin-driven).

Geopolitical shocks are no longer considered anomalies; they are the baseline operating environment. To remain competitive, textile firms must function like technology companies where AI is the Chief Strategist. The successful leader of 2026 is not the one who spots the next color trend, but the one who builds a resilient, autonomous, and data-transparent ecosystem. The Smart Factory 2.0 is no longer just a facility for making garments; it is a refinery for the data that grants a brand its license to operate.

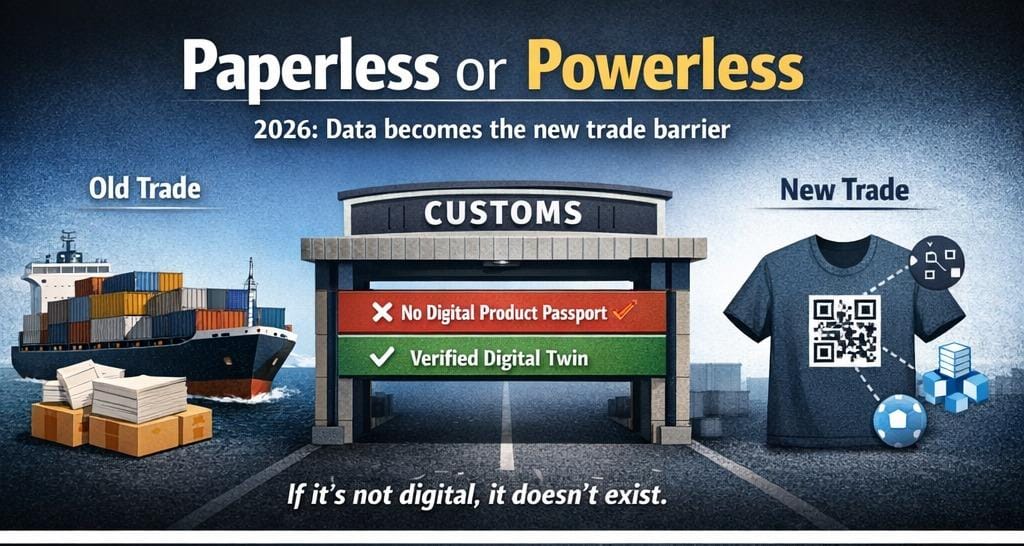

As we present this feature as part of our year-end series, 'Wrap Up 2025, Outlook 2026', the global textile and apparel industry is clearly moving beyond a simple calendar change. We are entering a period of "Radical Transparency" where the core of international trade is being rewritten. For decades, the primary hurdles in global trade were physical: quotas, shipping bottlenecks, and tariff brackets. However, as 2025 closes, a new barrier has emerged between manufacturing hubs like Dhaka and retail shelves in Paris. This wall is not made of brick or taxes, it is made of data.

The European Union’s Digital Product Passport (DPP), the regulatory centerpiece of the Ecodesign for Sustainable Products Regulation (ESPR), has moved from a boardroom concept to a mandatory operational requirement. With the EU’s central digital registry scheduled to become operational by July 2026, the mandate for global exporters is absolute: if a garment lacks a "Digital Twin"—a blockchain-verified record of its journey from fiber to finish—it is effectively invisible to customs authorities. In the high-stakes trade environment of 2026, being paperless increasingly means being powerless.

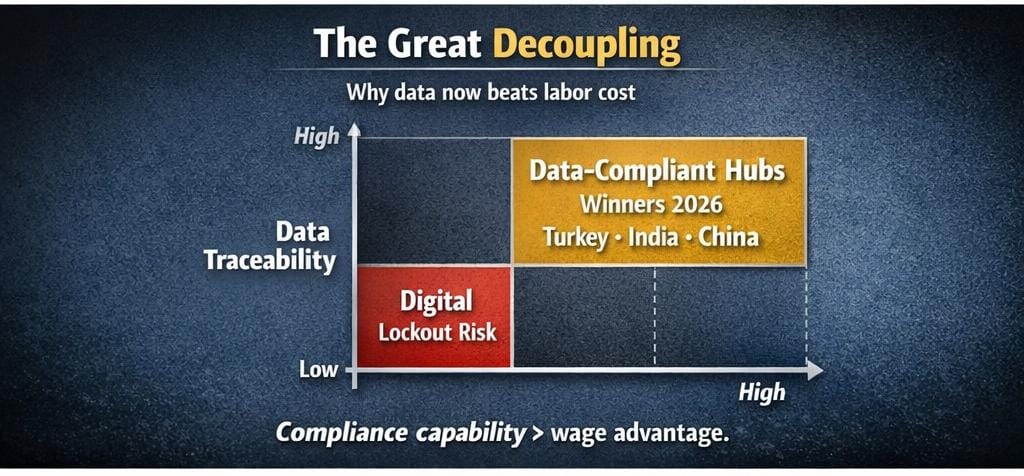

The Great Decoupling: Why data infrastructure outweighs labor cost

For thirty years, sourcing was a drive to minimize labor costs. In 2006, the industry moved toward speed; in 2016, toward quality. But as we map the 2026 trade landscape, a fundamental separation has occurred. Geography and proximity are being superseded by "Data-Traceability." Today’s C-Suite leaders recognize that a factory’s digital infrastructure; its ability to feed real-time, granular ESG metrics into a brand’s API, is now a more critical asset than its hourly wage rate. This has birthed the "Data-Compliant Hub." Countries like Turkey, with its integrated "Smart Mills," and India, leveraging its IT prowess to offer "DPP-as-a-Service," are emerging as the new victors. Conversely, regions that failed to digitize their Tier 2 and Tier 3 suppliers during the 2024-2025 transition are facing a "Digital Lockout."

The 2026 Macro-Indicator dashboard

The transition toward a data-centric trade model is reflected in the following market premiums and risk indicators observed as we enter the new year. These figures represent the emerging "Transparency Premium" that now dictates contract negotiations.

|

Indicator |

Market Impact (2025 Wrap Up) |

Forecasted Impact (2026 Outlook) |

|

Transparency Premium |

8-10% for verified organic cotton |

12-18% for full blockchain-traceable fiber |

|

Customs Rejection Risk |

<1% (Physical non-compliance) |

5-7% (Digital data discrepancies) |

|

Resale Value Multiplier |

15% for brand authentication |

35% for garments with full DPP history |

|

Non-Compliance Penalty |

Financial fines/Audit failures |

Total Market Exclusion / Port Impoundment |

Global Trade Scorecard: Winners, losers, and strategic outlook

The 2026 trade map is being redrawn based on a nation’s ability to prove its "Rules of Origin" through digital threads. Sourcing destinations are no longer judged solely on output volume but on the integrity of their data exports.

|

Country / Region |

2026 Trade Outlook |

Key Indicator: DPP Readiness |

Trade Policy & FTA Situation |

|

Turkey |

Winner |

High: Native blockchain integration in integrated mills. |

Near-shoring advantage; leveraging EU Customs Union for seamless data flow. |

|

India |

Rising |

Medium-High: PM MITRA parks and PLI 2.0 mandated for digital tracking. |

FTA with EU/UK hinges on digital verification of "Technical Textiles." |

|

Vietnam |

Vulnerable |

Medium: Automated at Tier 1; significant "Data Gaps" in raw material Tier 3. |

EVFTA benefits at risk if sustainability metrics cannot be digitally audited. |

|

Bangladesh |

Critical |

Low-Medium: High "Green Factory" count but lacks mid-stream data stacks. |

Transitioning from LDC status; urgent need for "Compliance-first" capex. |

|

China |

Pivot |

High: State-led green supply chains and proprietary "Trace-Tech." |

Moving from "World's Seamstress" to "World's Textile Tech Provider." |

The Regulatory Landscape: From voluntary to verified

The transition into 2026 is marked by the hardening of voluntary standards into strict legal frameworks. Beyond the DPP, the industry is grappling with the Corporate Sustainability Due Diligence Directive (CSDDD), which now mandates that companies take legal responsibility for environmental and human rights violations within their entire value chain. This regulatory pressure is amplified by the EU’s Carbon Border Adjustment Mechanism (CBAM), which has begun its data-collection phase for high-impact textiles. These regulations work in tandem to create a "triple threat" of compliance: the DPP tracks the product, the CSDDD tracks the process, and CBAM tracks the carbon. For manufacturers, this necessitates a complete overhaul of internal auditing. Compliance is no longer a periodic check but a continuous stream of verified data points.

Strategic Leadership: The CCO as the new power broker

This regulatory shift has fundamentally altered the organizational chart of the modern apparel house. The Chief Compliance Officer (CCO), once a back-office administrator, has emerged as the most influential broker in the boardroom. In 2026, the CCO often holds veto power over the Procurement Director; if a supplier cannot meet the "Data Package" requirement, the contract is dead on arrival, regardless of the price.

Strategic leadership is now defined by "Active Governance." CEOs are no longer satisfied with annual audits. They are deploying AI-augmented GRC (Governance, Risk, and Compliance) systems—digital agents that monitor the "digital shadow" of the supply chain in real-time. These systems can detect a "red flag"—such as an unverified cotton shipment or a spike in carbon intensity at a dyeing house—long before the physical goods reach a port of entry.

The "DPP Gold Rush" and the Tech-Sourcing nexus

The 2026 deadline has birthed a multi-billion dollar "Traceability Tech Stack" industry. Startups like Fashion Data (France) have moved beyond simple tracking; they use predictive algorithms to align DPP data with inventory, slashing the "guesswork" that led to the overproduction of the early 2020s. Retailers are no longer just selling clothes; they are selling "Data Packages" attached to garments. Consumers now scan QR codes not just for a "Made in" label, but to access repair instructions, recycled content percentages, and carbon footprint scores. This transparency has turned compliance into a competitive advantage: brands that embraced DPP early are reporting 15-20% higher customer loyalty scores, as traceability becomes the new hallmark of luxury and trust.

Editor’s Conclusion: The dawn of the "Trust Currency"

As we wrap up 2025, the narrative of the textile industry has changed from volume to veracity. The Digital Product Passport is not merely a bureaucratic hurdle; it is the new "Trust Currency" of global trade. For the C-Suite, the mandate for 2026 is clear: the era of "don't ask, don't tell" sourcing is officially over. The leaders who will thrive are those who stop viewing compliance as a cost center and start viewing it as the ultimate business intelligence tool. In a world where every stitch is recorded and every fiber is followed, the most successful brands will be those whose digital stories are as seamless as their physical seams. The 2026 trade map is being redrawn, and the ink is made of data.

The fashion world is witnessing a tectonic shift as Prada Group moves to integrate its recent acquisition of Versace, a merger that pits Prada’s trademark ‘intellectual minimalism’ against Versace’s ‘unapologetic glamour.’ Industry analysts, including Luca Solca, suggest this ‘New Italian Order’ is a calculated effort to back Versace’s immense cultural power with Prada’s legendary operational efficiency. While Versace has long dominated pop culture with its logo-heavy, Mediterranean aesthetic, it has recently struggled with a "shaky present" and an over-dependence on outlet malls. Patrizio Bertelli, Chairman, Prada Group has emphasized that the goal is not to dilute Versace’s voice but to provide a ‘strong platform reinforced by years of ongoing investments,’ effectively using discipline to save decadence.

Navigating the high-stakes path to global premiumization

The road ahead is defined by a rigorous ‘premiumization’ strategy, aiming to transition Versace away from discounted retail and toward high-margin, exclusive positioning. Andrea Guerra, CEO, Prada has signaled a three-year window to prove whether this organizational discipline can sharpen Versace's spectacle or if it will inadvertently dull its edge. The group is eyeing aggressive expansion in underpenetrated markets like Southeast Asia and the Middle East, leveraging a revenue base that is currently diversified across EMEA (42 per cent) and the Americas (31 per cent). However, the journey faces immediate hurdles, most notably the ‘sudden exit’ of creative lead Dario Vitale, which complicates Prada’s promise of stability. As the Prada-Bertelli family maintains an 80 per cent stake in the group, the focus remains on vertical integration and consistent product identity to ensure this Italian luxury renaissance yields long-term financial growth.

Established in 1913 by Mario Prada, the Prada Group is a global leader in luxury leather goods and ready-to-wear fashion. The company is currently executing a massive portfolio expansion, fueled by a verticalized global network and streamlined supply chains. With a goal of re-establishing heritage brands like Versace as premium icons, the group is targeting high-growth markets to secure its financial future.

The International Association of Department Stores (IADS) 2025 review reveals a stunning reversal for the ‘traditional’ format, with members reporting record-breaking profits by prioritizing luxury and digital agility. Bloomingdale’s led the pack with a 9 per cent surge in comparable sales - its strongest performance in 13 years - while Mexico’s El Palacio de Hierro saw revenues jump 12 per cent to $1.47 billion in H1. This growth significantly outpaces the broader retail sector, which averaged just 3.2 per cent growth in same-store sales globally. ‘Discipline meets creativity when stores operate with a purpose beyond the shelf,’ notes IADS leadership, highlighting a shift where digital sales now contribute up to 60 per cent of GMV for leaders like Germany's Breuninger.

The flagship as a living brand universe

The physical store is being reborn as an ‘experiential destination,’ exemplified by Galeries Lafayette’s 90,000 sq ft Mumbai debut in November 2025. Developed with Aditya Birla Group, the site hosts 250+ luxury brands, blending French heritage with Mumbai’s cultural vitality. Meanwhile, Breuninger’s 13,000 sq m Hamburg flagship serves as a case study in ‘phygital’ fusion, integrating AI-driven personal shopping suites. Despite these successes, the sector faces the hurdle of skyrocketing operational costs for high-density mall footprints. However, the resilience of TSUM Kyiv - which added 52,000 new clients and exceeded 2021 pre-war performance - underscores that when retail serves communities through crisis, brand loyalty becomes unshakeable.

Digital sovereignty and AI-driven retail media

Beyond the sales floor, retailers are monetizing data through premium retail media propositions, a move championed by John Lewis & Partners. The Chalhoub Group has further disrupted the landscape with ‘Alia,’ its proprietary GenAI platform, automating customer engagement across 39 new store openings. This transition from ‘merchant to landlord and media hub’ represents a fundamental sector shift. As El Corte Inglés deploys its €3 billion investment plan, the 2025 data confirms that the department store’s future lies in its ability to act as a cultural anchor, blending high-fashion exclusivity with hyper-personalized digital convenience.

Founded in 1928, the International Association of Department Stores (IADS) is the oldest international retail body, representing giants from Bangkok to Paris. It facilitates strategic exchange on digital transformation and sustainability, guiding members toward record profitability. The association drives growth by future-proofing the department store model through experiential innovation.

The International Association of Department Stores (IADS) 2025 review reveals a stunning reversal for the ‘traditional’ format, with members reporting record-breaking profits by prioritizing luxury and digital agility. Bloomingdale’s led the pack with a 9 per cent surge in comparable sales - its strongest performance in 13 years - while Mexico’s El Palacio de Hierro saw revenues jump 12 per cent to $1.47 billion in H1. This growth significantly outpaces the broader retail sector, which averaged just 3.2 per cent growth in same-store sales globally. ‘Discipline meets creativity when stores operate with a purpose beyond the shelf,’ notes IADS leadership, highlighting a shift where digital sales now contribute up to 60 per cent of GMV for leaders like Germany's Breuninger.

The flagship as a living brand universe

The physical store is being reborn as an ‘experiential destination,’ exemplified by Galeries Lafayette’s 90,000 sq ft Mumbai debut in November 2025. Developed with Aditya Birla Group, the site hosts 250+ luxury brands, blending French heritage with Mumbai’s cultural vitality. Meanwhile, Breuninger’s 13,000 sq m Hamburg flagship serves as a case study in ‘phygital’ fusion, integrating AI-driven personal shopping suites. Despite these successes, the sector faces the hurdle of skyrocketing operational costs for high-density mall footprints. However, the resilience of TSUM Kyiv - which added 52,000 new clients and exceeded 2021 pre-war performance - underscores that when retail serves communities through crisis, brand loyalty becomes unshakeable.

Digital sovereignty and AI-driven retail media

Beyond the sales floor, retailers are monetizing data through premium retail media propositions, a move championed by John Lewis & Partners. The Chalhoub Group has further disrupted the landscape with ‘Alia,’ its proprietary GenAI platform, automating customer engagement across 39 new store openings. This transition from ‘merchant to landlord and media hub’ represents a fundamental sector shift. As El Corte Inglés deploys its €3 billion investment plan, the 2025 data confirms that the department store’s future lies in its ability to act as a cultural anchor, blending high-fashion exclusivity with hyper-personalized digital convenience.

Founded in 1928, the International Association of Department Stores (IADS) is the oldest international retail body, representing giants from Bangkok to Paris. It facilitates strategic exchange on digital transformation and sustainability, guiding members toward record profitability. The association drives growth by future-proofing the department store model through experiential innovation.

The global fashion retail landscape is witnessing a structural shift as Bangladesh’s ready-made garment (RMG) sector moves beyond its traditional identity as a low-cost volume hub. While fiscal year 2025 closed with a robust 8.84 per cent increase in apparel exports to $39.35 billion, the underlying narrative is one of rapid technological deepening and stringent environmental compliance.

Faced with a 33 per cent rise in industrial gas prices and a statutory wage review, manufacturers are aggressively integrating automated cutting, knitting, and sewing lines. This capital-intensive transition has boosted factory productivity several fold, allowing the sector to absorb rising overheads while maintaining its edge against regional competitors like Vietnam and China.

Green manufacturing as a competitive advantage

Sustainability has evolved from a boardroom buzzword into a prerequisite for market access. Bangladesh now hosts over 240 LEED-certified green factories, the highest globally, positioning it as the preferred partner for European and North American brands adhering to new circularity mandates. Led by BGMEA, the ‘Sustainability Vision 2030’ targets a 30 per cent reduction in greenhouse gas emissions, underpinned by a surge in rooftop solar installations and water-recycling technologies. This ‘green premium’ is attracting high-value orders in the athleisure and technical textile segments, which are projected to grow at a 6.7 per cent CAGR through 2030.

Navigating tariff shocks and LDC graduation

Despite the momentum, the industry faces immediate headwinds from shifting trade policies. In a significant diplomatic breakthrough in late 2025, a negotiated 20 per cent cap on US tariffs averted a more punitive 35 per cent rate, though duties remain higher than historical levels. The sector is also bracing for the 2026 LDC graduation, which will phase out preferential market access. Manufacturers like the DBL Group are responding by diversifying into synthetic fibers and recycled polyester - sub-segments expected to exceed $8 billion by 2030 - ensuring the ‘Made in Bangladesh’ tag remains indispensable in an era of ethical and high-performance fashion.

As the world’s second-largest apparel exporter, Bangladesh’s RMG sector accounts for 85 per cent of national export earnings. Dominating in knitwear and woven categories, the industry is currently transitioning toward high-value functional textiles and automation to offset rising labor costs. With a 2030 export target of $100 billion, the sector remains the bedrock of national economic stability and female workforce empowerment.