FW

Criticising the Finance Bill 2024 for imposing additional burden on the textile units, potentially leading to the collapse of the entire sector, the All Pakistan Textile Mills Association (APTMA) has urged the Federal Board of Revenue (FBR) to reconsider the destructive measures proposed in the bill.

During a meeting with the FBR Chairman, APTMA vehemently protested the regressive and punitive tax and customs-related measures proposed in the Finance Bill 2024, describing them as an existential threat to Pakistan’s textile industry. APTMA argued, these measures may unequivocally damage this vital sector, undermining Pakistan’s economic stability and export capacity.

A few of the key concerns raised by APTMA included withdrawal of the zero-rating on local inputs for export manufacturing that may disadvantage domestic and cloth producers, imposition of a 2 per cent custom duty on cotton and MMF, a 2 per cent advance tax on export proceeds, liquidity crisis in the industry and high duties on PTA/PSF.

Besides exacerbating the current situation, the proposed measures may deter new investment in productive, export-oriented activities, leading to a decline in industrial capacity and increasing capital flight to the informal sector, said APTMA. This will reduce government revenue and worsen the fiscal deficit, creating a vicious cycle of economic decline and increasing the risk of sovereign default, it added.

A study conducted by QR Code Generator Pro SL names Kim Kardashian'sSkims as the world's leading celebrity clothing brand.

The study was conducted using multiple metrics to determine the rankings, including Trustpilot reviews, Instagram followers, and search data from Google Keyword Planner. Specialising in shapewear, loungewear, and underwear, Skims topped the list with an index score of 79.93 out of 100. The brand garners over 3.4 million Google searches per month, the highest among all the brands analysed, while on Instagram, it boasts a following of 5.9 million users.

The second spot was secured by Rihanna’s Savage X Fenty with an index score of 66.34, recording more than 384,000 monthly searches and an Instagram following of 5.1 million. Meanwhile, Fabletics by actress Kate Hudson ranked third with an overall score of 52.11. The activewear brand has a community of 1.95 million Instagram followers, and gets 1.3 million monthly searches for terms related to its products.

Rounding out the top five is Kanye West’s brand Yeezy, with an index score of 51.98, in fourth place, followed by KhloeKardashian’s Good American with a score of 47.45.

Several other celebrity brands also made it into the top ten with the Jessica Simpson Collection (33.88) and Emily Ratajkowski's Inamorata (33.67) placing sixth and seventh, respectively. Fashion powerhouse Stella McCartnery secured the eighth spot with a score of 25, while Beyoncé’s Ivy Park (23.11) and Drake’s October’s Very Own (14.35) completed the top ten.

Marc Porcar, CEO, QR Code Generator Pro SL, says, the findings reinforce that impressive and renowned empire created by the Kardashian family – beginning in reality TV and culminating in globally recognized and consumer-favorite clothing brands, Skims and Good American are the only two brands that rank in the top ten most popular in the world – topping even fashion royalty, like Stella McCartney.

Karl MayerTechnischeTextilien is making waves in the wind power industry with the launch of their Max Glass Eco machine. This innovative machine focuses on producing standard non-crimp fabrics from glass fibers, crucial for reinforcing wind turbine rotor blades.

The Max Glass Eco stands out for its perfect balance of affordability and performance. It combines proven technology from previous models like the Maxtronic with new advancements, resulting in a highly economical machine for standard glass fiber applications.

Karl Mayer complements its product portfolio with the Max Glass Eco. While Cop Max 4 caters to demanding applications with its extensive customization options, the Max Glass Eco is ideal for high-volume production of standard glass fiber products.

The Max Glass Eco boasts an impressive production rate of 410 m/h at a speed of 1800 min-1. It offers a working width of 101″ and features a fixed layer system for exceptional placement precision. Additional innovations include a conveyor belt, a walking needle system, and single compound needles for efficient operation.

The Max Glass Eco has been met with great enthusiasm. Its short amortization times and attractive price point have garnered significant interest from potential customers across Eastern Europe, India, and Asia.

Max Glass Eco paves the way for efficient and cost-effective production of glass fiber components in the wind power industry.

According to the latest import and export data, Indian cotton yarn exports (HS code 5205) increased by 14.54 per cent Y-o-Y to 87,637.26 tons in April 2024. However, these yarn exports registered a 16.25 per cent M-o-M decline during April 2024.

In April, India’s yarn exports to China declined by 51.36 per cent Y-o-Y and 59.72 per cent M-o-M in April. China's market share in Indian cotton yarn exports dropped to around 5 per cent, declining by 6 per cent compared to March 2024.

Bangladesh continues to be the largest export destination for Indian cotton yarn, holding approximately 43 per cent of the export market,. Portugal and Vietnam follow with shares of 7 per cent and 6 per cent respectively. The fourth position is jointly occupied by Egypt and China. The market shares of other countries' remained below 5 per cent, with some showing increases or stability compared to March, except for Vietnam, China, Egypt, and Peru, which saw declines.

In summary, Indian cotton yarn exports in April 2024 exhibited a year-on-year increase but a month-on-month decrease. The key export markets were Bangladesh, Portugal, Vietnam, and China. Exports to China experienced significant reductions both year-on-year and month-on-month. Among the four main types of Indian yarns exported to China, carded single yarn 8-25s had the largest export quantity.

For the 2024-25 marketing season, the Indian government has raised the Minimum Support Prices (MSP) for cotton by over 7 per cent. Approved by the Union Cabinet under Prime Minister NarendraModi, this decision applies to all mandated Kharif crops for the season. According to sources within the Indian textile industry, this increase is expected to elevate production costs throughout the value chain.

As per a recent government press release, the MSP for medium staple cotton (known as seen cotton) will increase by 7.56 per cent to Rs7,121 per quintal from Rs 6,620 per quintal. MSP for long staple cotton will rise by 7.13 per cent to Rs7,521 per quintal from Rs7,020 per quintal. The new MSPs will be implemented by the government’s nodal agency, Cotton Corporation of India (CCI).

Industry experts believe,the MSP increase will boost production costs for ginners and spinners due to the elevated cotton prices. While the market price of cotton is expected to stay above the MSP level, there is uncertainty regarding whether spinners, fabric, and garment manufacturers will be able to pass on these increased costs to their buyers. This concern is compounded by the current sluggish global demand for textiles.

Leading global sewing equipment manufacturer, Jack Technology launched the groundbreaking 'Urus' overlock machine in Guangzhou, China. Named after the Lamborghini Urus for its speed and precision, this innovative machine is designed to handle any fabric with ease.

Jack Technology also showcased this machine at the 2024 New Product Conference that was broadcasted to over 30 sub-venues in China, Cambodia, Vietnam, and other countries. The event attracted numerous industry specialists and scholars, including the chairman of the China Sewing Machinery Association, vice president of the China Garment Association, and leaders from garment associations in India and Bangladesh, marking a significant milestone in the sewing equipment industry.

With the rise of fashion and personalised clothing, the sewing and textile industry is shifting towards a "small orders and quick reorders" model. Traditional overlock machines often face issues such as fabric wrinkling, needle breakage, and thread snapping, particularly with mixed fabrics like thick, thin, elastic, and hard materials.

To address these challenges, Jack Technology integrated AI technology into their sewing equipment. The company collaborated with top universities and research institutes, including Stanford University, the Chinese Academy of Sciences, Tsinghua University, and Zhejiang University for developing the Urusoverlock machine.

Equipped with an industry-leading AI full-speed feeding system, the Urus machine handles various fabric types and thicknesses seamlessly. It boasts a 'super brain' with a pressure-to-feed ratio model library, enabling multimodal intelligent detection of fabric thickness changes at a rate of 32,000 times per second. This ensures the machine can adjust the pressing and feeding force parameters in real-time.

Key technologies in Urus include the Presser Foot Transformer and Smart Rhino Feeding. The Presser Foot Transformer adjusts pressure distribution in 0.00006 seconds, while Smart Rhino Feeding provides precise power distribution, achieving a perfect match between pressure and delivery forces. During the conference, URUS demonstrated its ability to handle different fabrics, such as hoodies, jeans, yoga suits, and mesh yarn, all with perfect stitches.

At the conference, Jack Technology announced plans to promote unmanned research and development, integrating software, hardware, and AI technology to gradually achieve unmanned production using various templates and humanoid robots. This vision aims to usher in a new era of intelligent production. Jack Ruan, Founder and CEO, Jack Technology, emphasises their commitment to innovation and customer value. "As long as the company continues to focus on creating value for customers, keeps innovating sewing technology, endeavors to develop intelligent total solution for sewing industry, it can breakthrough any challenges like the Urus.

The recent Intertextile Shenzhen Apparel Fabrics concluded its 2024 edition on a high note, solidifying its position as a premier trade show for the textile industry. The event, held from June 5th to 7th, served as a key meeting point for industry leaders, showcasing the latest trends and innovations in fabrics and apparel.

Sustainability on the rise

“A major takeaway was the growing emphasis on eco-friendly materials and production processes”, says Joanna Chen, Sales Manager from Shanghai Shileju Textile, company that focuses on sustainable and eco-friendly materials. She pointed out the abundance of exhibitors showcasing innovative textiles made from recycled materials, reflecting a global demand for environmentally conscious products.

Felicia Shi, Regional Representative for the Global Organic Textile Standard (GOTS), reported a positive response from attendees, particularly SMEs, to their first-time presentation at the event. She highlighted the potential for new collaborations in promoting sustainable practices within the textile industry. GOTS is a non-profit organization that manages the Global Organic Textile Standard, which certifies organic textiles. She observed the participation of many exhibitors with GOTS certification. This reflects the growing demand for eco-friendly textiles, aligning with the show's commitment to innovation and responsibility.

Felicia Shi, Regional Representative for the Global Organic Textile Standard (GOTS), reported a positive response from attendees, particularly SMEs, to their first-time presentation at the event. She highlighted the potential for new collaborations in promoting sustainable practices within the textile industry. GOTS is a non-profit organization that manages the Global Organic Textile Standard, which certifies organic textiles. She observed the participation of many exhibitors with GOTS certification. This reflects the growing demand for eco-friendly textiles, aligning with the show's commitment to innovation and responsibility.

Innovation across the spectrum

Beyond sustainability, the event offered a comprehensive overview of textile resources, according to Sajjad Mazahir, Director Marketing of Keywin Trading & Hong Kong Cheung Wick Ltd., Guangzhou, companies that supply resources for the apparel trade, including fibers, yarns, apparel, and accessories. “From fibres and yarns to finished apparels and accessories, the exhibition covered the entire garment production cycle. Exhibitors showcased a wide range of materials, including cotton, man-made fibres, and innovative functional fabrics with water repellency, breathability, and wrinkle resistance” says, Sajjad.

Vivian Su of Suzhou Huahe Textile, manufacturer of anti-pilling fabrics, highlighted the focus on product innovation by their company showcasing their latest developments in fabric functionalities and production techniques. Vivian emphasized the importance of continuous product innovation to stay competitive.

Vivian Su of Suzhou Huahe Textile, manufacturer of anti-pilling fabrics, highlighted the focus on product innovation by their company showcasing their latest developments in fabric functionalities and production techniques. Vivian emphasized the importance of continuous product innovation to stay competitive.

Rui Zhang of XYX Materials, manufactures of fabrics for intimate apparel, shapewear, swimwear, and yoga leggings, too echoed this sentiment, adding, he finds emerging opportunities due to a focus on outerwear and coarser fabrics.

Footfall and visitors’ number reflect market situation

A recurring theme in the feedback was a much higher than the previous year event footfall, yet lower-than-expected visitor turnout, on the back of lower demand in the export and domestic market of China. Leah Jiashan of Yongli Lai Garment Accessories, a manufacturer of garment accessories such as buckles, buttons, eyelets, and zippers; as well as Sajjad Mazahir attributed this to weak downstream demand, particularly in export markets surrounding Shenzhen.

Looking Forward

Looking Forward

The event provided valuable insights for future industry gatherings. Joanna Chen is confident that the knowledge gained will enhance their presentation at the upcoming Intertextile Shanghai.

Intertextile Shenzhen 2024 served as a microcosm of the textile industry's current landscape, navigating a path towards sustainability while facing ongoing challenges in a globalized market.

Following extensive trials, French sportswear brand Decathlon has launched a unique knitting technique for its new Negombo fabric. Introduced in Decathlon Nabaiji swimwear, this innovative fabric has been made from recycled feedstocks, and is both recyclable and eco-friendly.

Eliminating the use elastane, the Negombo fabric utlises a combination of Lycra’s T400eco fiber and recycled PET. Decathlon's special knitting technique enables the fabric to retain its shape and stretchiness over time. Impressively, 76 per cent of the fabric's fibers are recycled.

To establish a fabric-to-fabric circular reprocessing route, Decathlon is also developing a recycling process for Negombo fabric with various partners.

Laboratory tests show that Negombo fabric has a chlorine resistance of over 500 hours, significantly enhancing its durability. Additionally, the polyester-based fabric can be printed using sublimation techniques, reducing CO2 emissions by 60 per cent compared to conventional dyeing. With 210 grams of opacity, the fabric eliminates the need for a liner, saving material and ensuring faster drying. The fabric also offers a UV protection factor of over 50.

To further enhance its new Nabaiji apparel line, Decathlon has partnered with Resortecs, a Brussels-based company focused on making recycling more feasible through innovative design-for-disassembly technologies. Resortecs' Smart Stitch technology includes a range of 16 heat-dissolvable sewing threads, compatible with all stitching machines and available in various colors and strengths. These threads dissolve at temperatures between 150 and 190 degrees, depending on the fiber type, facilitating the disassembly of fabrics and making it easier to recycle unsold inventory. Garments using Smart Stitch threads can be washed, ironed, and laundered without any issues during their lifetime.

Resortecs' complementary technology, Smart Disassembly, is a patented industrial-scale thermal disassembly system with a flexible capacity of 1-13 tons per day and a processing speed five times faster than manual disassembly. This system operates in low-oxygen chambers to prevent oxidation damage and uses a closed-loop heating system that maximizes energy recovery and minimises CO2 emissions.

Together, Decathlon's innovations in fabric technology and Resortecs' advancements in recycling processes are setting new standards for sustainable and durable swimwear.

Intertextile Shenzhen Apparel Fabrics 2024 wasn't just about showcasing products. The 2024 edition of Intertextile Shenzhen Apparel Fabrics concluded after a successful three-day run at the Shenzhen Convention & Exhibition Center in Futian. The event, which took place from June 5th to 7th, served as a platform for industry leaders to convene and share expertise. Visitors were treated to a series of fringe events featuring experts from organizations like HKRITA, Pantone, and the Nano and Advanced Materials Institute (NAMI). These events provided valuable insights into the cutting edge of the textile industry.

Revolutinising Textile Recycling

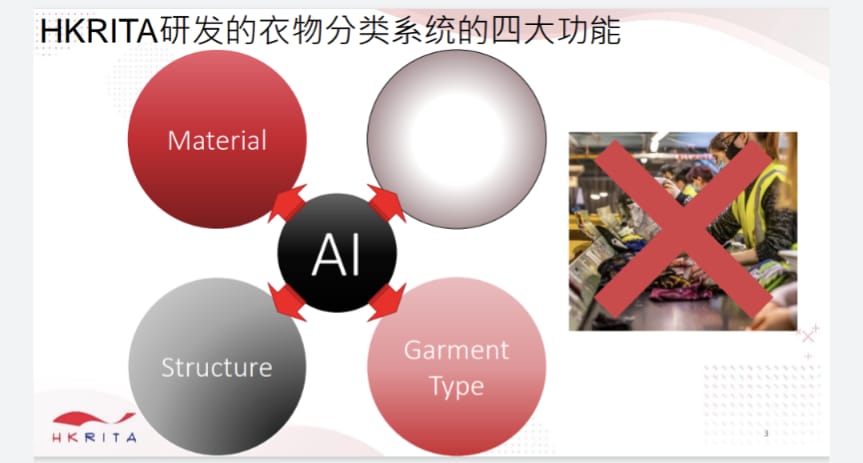

To address the issue of Textile Recycling, Raymond Chiu, Senior Research Manager, HKRITA made a presentation during the event on AI-powered garment sorting system that HKRITA has developed that can accurately classify and sort used textiles for recycling. This innovative technology has the potential to revolutionize the textile recycling industry and make a significant contribution to environmental sustainability.

Key Features of the AI-Powered Garment Sorting Syste

The AI-powered garment sorting system utilizes a combination of advanced technologies, including:

• Hyperspectral imaging: This powerful imaging technique allows the system to identify the chemical composition of textiles, even in blended materials. This is crucial for accurately sorting textiles for recycling, as different fibers require different recycling processes.

• Image recognition: The system uses advanced image recognition algorithms to identify the type of garment, such as a t-shirt, jeans, or dress. This information can be used to further optimize the sorting process and ensure that textiles are recycled into the most appropriate products.

• Machine learning: The system is continuously learning and improving its accuracy as it processes more data. This means that it can become more effective at sorting textiles over time.

Benefits of the AI-Powered Garment Sorting System

The AI-powered garment sorting system offers a number of benefits, including:

• Improved recycling efficiency: By accurately sorting textiles, the system can help to ensure that they are recycled into the most appropriate products. This can lead to higher-quality recycled materials and a reduction in waste.

• Reduced environmental impact: By diverting textiles from landfills and incinerators, the system can help to reduce the textile industry's environmental footprint.

• Increased economic value: The system can help to create new markets for recycled textiles, which can lead to increased economic opportunities for the textile industry.

Application in Jeans Recycling

HKRITA has developed a specific solution for recycling used jeans, focusing on the recovery of the warp yarn. This solution utilizes the AI-powered garment sorting system to identify and separate the warp yarn from the weft yarn and other components of the jeans. The recovered warp yarn can then be recycled into new denim products.

Potential to transform textile recycling

The AI-powered garment sorting system is a promising technology that has the potential to transform the textile recycling industry. By improving recycling efficiency, reducing environmental impact, and increasing economic value, this system can play a significant role in creating a more sustainable textile industry.

The fashion industry is set to witness a significant shift towards intuitive design at the upcoming Munich Fabric Start event on September 3-4, 2024. Held in Munich, this premier European trade show will spotlight innovations and aesthetically demanding trends under the guiding theme of "Intuition". By encouraging designers and fashion creators to rely more on their instincts, the event aims to foster creativity and inspire new directions in the fashion world.

A hub of innovation and creativity

Spanning 42,500 square meters, Munich Fabric Start will host around 1,000 collections from international premium manufacturers, making it a central meeting point for the European fashion scene. The event is structured into eight focused areas: Additionals, Fabrics, Resource, Bluezone, Design Studios, Keyhouse, Sustainable Innovations, and TheSoutce. These sections provide a comprehensive overview of the latest developments in the industry, offering insights into new trends, innovative materials, and cutting-edge technologies.

Highlights and key events

One of the most anticipated highlights is a live lecture by globally recognized trend forecaster Li Edelkoort. Scheduled for September 4, 2024, Munich, Edelkoort will share her insights and trend forecast for the Autumn/Winter 2025/26 season. This private lecture promises to provide invaluable guidance for designers and fashion professionals seeking to stay ahead of the curve.

In response to the industry's demand for more focused events, the show has been compressed from three days to two. This strategic decision addresses current market trends and aligns with the evolving needs of exhibitors and visitors, emphasizing efficiency and reducing travel time.

Comprehensive sourcing solutions

Munich Fabric Start stands out as an unparalleled all-in-one sourcing solution, bringing together the entire fashion ecosystem. The event promises short distances between exhibits, a highly professional working environment, and a central, internationally well-connected location in the heart of Europe. Attendees will find numerous familiar faces and a vibrant atmosphere conducive to networking and business development.

Sebastian Klinder, Managing Director of Munich Fabric Start, highlights the event's unique blend of aesthetic and commercial pioneering. "The upcoming Munich Fabric Start offers an inspiring journey to our intuition. In a dynamic industry constantly shaped by innovations and changes, we create a platform that is both aesthetically and commercially pioneering."

Diverse exhibitor line-up

The Fabrics section will showcase the latest collections from leading manufacturers, featuring innovative and sustainable materials. Exhibitors include Akin, Albini, Dutel, Erica, Fortex, Getzner, Iskur, Liberty, Malhia Kent, Manteco, and many others.

The Additionals section will present the latest trends and developments in trimmings and accessories, with exhibitors like Cadica Group, Escher Textil, BornemannEtiketten, EU / Fenili, Maxim, Nilorn, Panama Trimmings, and YKK Group setting important accents for upcoming collections.

The Source will focus on production and sourcing, highlighting sustainable and innovative processes with exhibitors such as DMISS Textile Group, Evotex, Lagoon Limited, M360 -Miroglio Group, Ningbo Wollamtex Apparel & Co. Ltd., and Thai Son Knitwear Factory.

Denim and technological innovations

Bluezone, under the motto Denimined, will center on denim and streetwear, featuring about 100 collections from renowned weavers. The emphasis will be on themes like circular economy, recycling, and upcycling. Additionally, the Denim Deal will unveil its first signatories in Germany.

Keyhouse, themed Techknowledge, will showcase progressive suppliers and global players presenting their latest technological and sustainable innovations. Highlights include Adidas' T-Rex Project for recycling post-consumer textile waste and Biotex future Transition Lab's Bio Turf, Light Lining, and Fungal Fibers projects.

Future prospects and events

Looking ahead, the View Premium Selection will kick off the Autumn/Winter 2025/26 season on June 26-27, 2024, featuring over 260 collections in segments like Fabrics, Additionals, Denim, and Sportswear. The new interim location in downtown Munich, known as B-Tween, promises an optimal setting for the Preview Textile Show.

Overall, Munich Fabric Start 2024 is set to be a transformative event, emphasizing intuition and innovation in the fashion industry. With its diverse offerings and strategic focus, it will undoubtedly inspire designers and fashion creators to explore new horizons and incorporate trends into their collections.